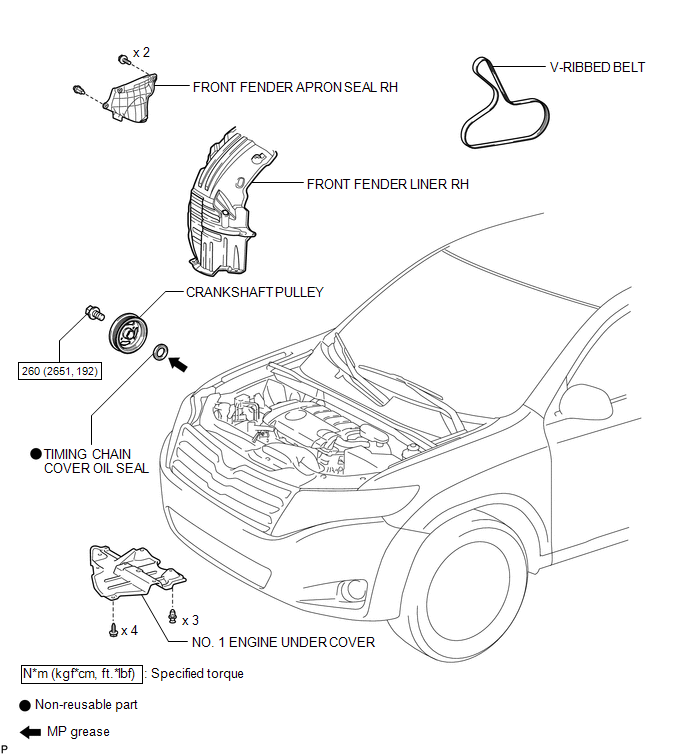

Toyota Venza: Front Crankshaft Oil Seal

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE NO. 1 ENGINE UNDER COVER

3. SEPARATE FRONT FENDER LINER RH

4. REMOVE FRONT FENDER APRON SEAL RH

.gif)

5. REMOVE V-RIBBED BELT

.gif)

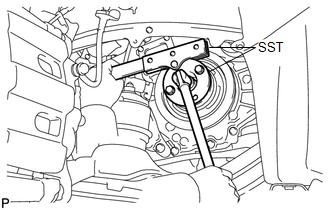

6. REMOVE CRANKSHAFT PULLEY

|

(a) Using SST, hold the crankshaft pulley and loosen the pulley bolt. Further loosen the bolt until 2 or 3 threads are screwed into the crankshaft. SST: 09213-54015 SST: 09330-00021 HINT: Part number of installation bolt for SST (crankshaft pulley holding tool): 91551-80650 (quantity: 2) |

|

|

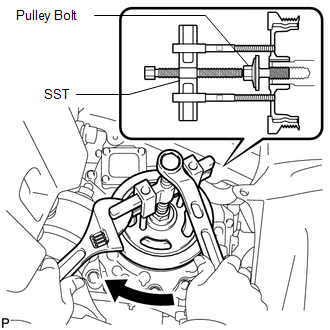

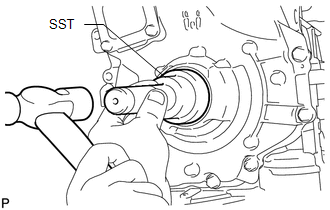

(b) Using SST and the pulley bolt, remove the crankshaft pulley. SST: 09950-50013 09951-05010 09952-05010 09953-05020 09954-05011 HINT: Apply a lubricant to the threads and end of SST. |

|

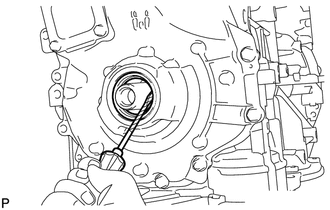

7. REMOVE TIMING CHAIN COVER OIL SEAL

|

(a) Using a screwdriver, pry out the oil seal. HINT: Tape the screwdriver tip before use. NOTICE: Do not damage the surface of the oil seal press fit hole or the crankshaft. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL TIMING CHAIN COVER OIL SEAL

(a) Apply MP grease to the lip of a new oil seal.

NOTICE:

- Do not allow foreign matter to contact the lip of the oil seal.

- Do not allow MP grease to contact the dust seal.

|

(b) Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge. SST: 09223-22010 NOTICE:

|

|

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the crankshaft pulley.

|

(b) Using SST, hold the crankshaft pulley and install the pulley bolt. SST: 09213-54015 SST: 09330-00021 Torque: 260 N·m {2651 kgf·cm, 192 ft·lbf} HINT: Part number of installation bolt for SST (crankshaft pulley holding tool): 91551-80650 (quantity: 2) |

|

3. INSTALL V-RIBBED BELT

.gif)

4. INSTALL FRONT FENDER APRON SEAL RH

.gif)

5. INSTALL FRONT FENDER LINER RH

6. INSTALL NO. 1 ENGINE UNDER COVER

7. INSTALL FRONT WHEEL RH

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL STIFFENING CRANKCASE RING PIN

NOTICE:

It is not necessary to remove the ring pin unless it is being replaced.

(a) Using a plastic-faced hammer, tap in 2 ...

Other materials about Toyota Venza:

Entry Interior Alarm does not Sound

DESCRIPTION

The smart key system uses the combination meter buzzer to perform various vehicle

interior warnings. When the conditions for each warning are met, the certification

ECU (smart key ECU assembly) sends a buzzer signal to the combination meter as ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL MANUAL VALVE

(a) Coat the manual valve with ATF and install it to the transmission

valve body assembly.

2. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) Coat th ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK BATTERY CONDITION

NOTICE:

If the battery is weak or if the engine is difficult to start, perform the following

procedure.

(a) Check the battery for damage or deformation. If severe damage, deformation

or leakag ...

0.1342

.png)