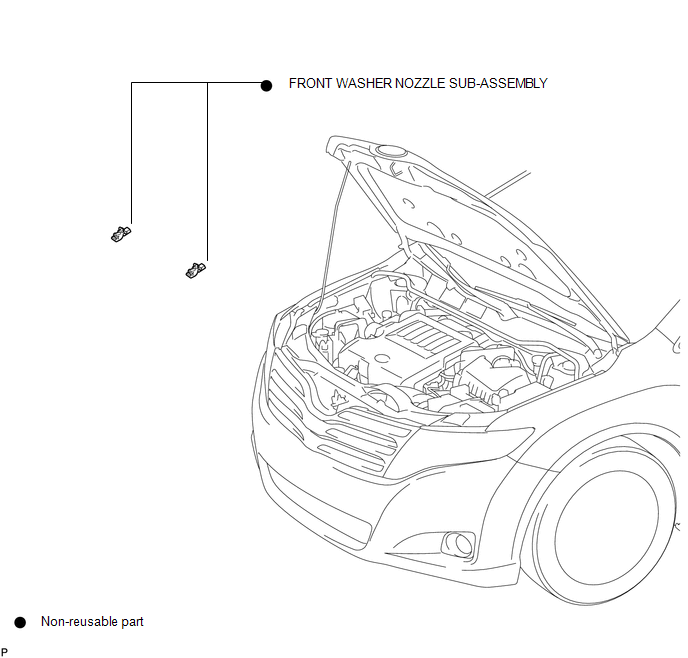

Toyota Venza: Washer Nozzle(for Front Side)

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

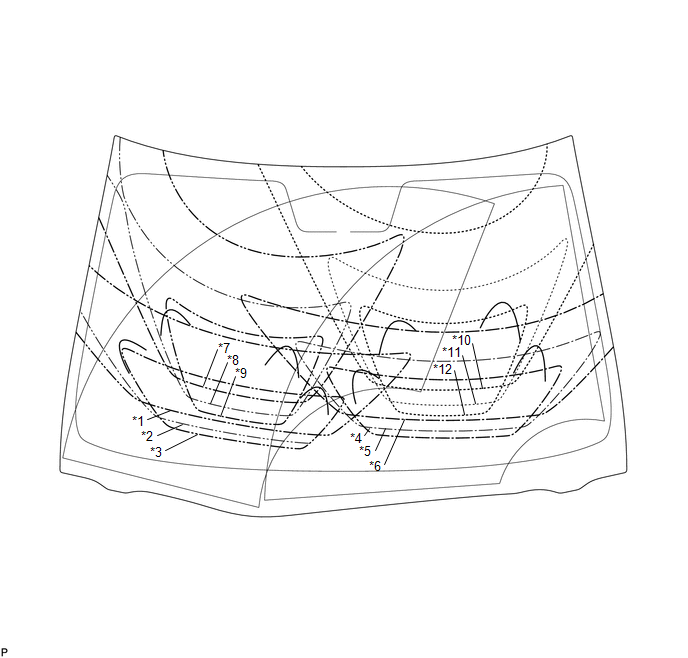

1. INSPECT FRONT WASHER NOZZLE SUB-ASSEMBLY

(a) With the engine running, check that the center stream of washer fluid sprays on the windshield within the area shown in the illustration.

OK:

Washer fluid hits the windshield in the area shown in the illustration.

If the result is not as specified, replace the washer nozzle.

Text in Illustration

Text in Illustration

|

*1 |

Front Passenger Side Lower Maximum Spray |

*7 |

Front Passenger Side Upper Maximum Spray |

|

*2 |

Front Passenger Side Lower Nominal Spray |

*8 |

Front Passenger Side Upper Nominal Spray |

|

*3 |

Front Passenger Side Lower Minimum Spray |

*9 |

Front Passenger Side Upper Minimum Spray |

|

*4 |

Driver Side Lower Maximum Spray |

*10 |

Driver Side Upper Maximum Spray |

|

*5 |

Driver Side Lower Nominal Spray |

*11 |

Driver Side Upper Nominal Spray |

|

*6 |

Driver Side Lower Minimum Spray |

*12 |

Driver Side Upper Minimum Spray |

Adjustment

ADJUSTMENT

PROCEDURE

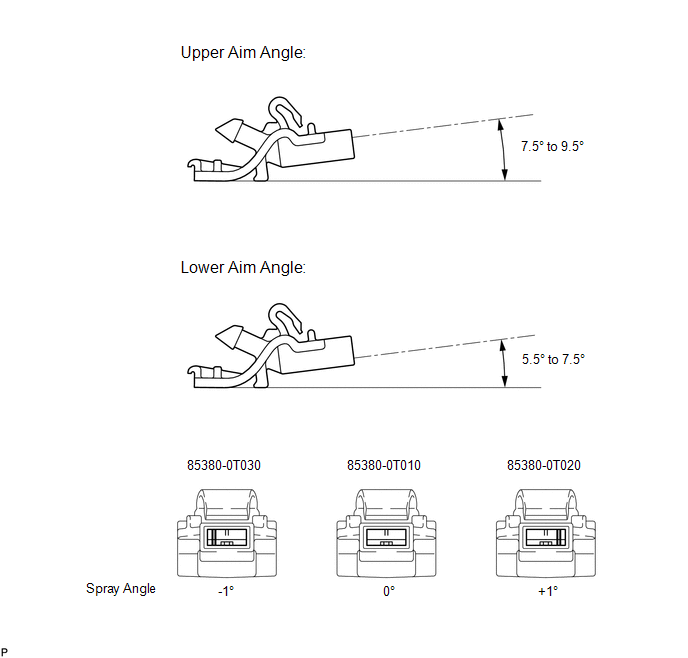

1. ADJUST FRONT WASHER NOZZLE SUB-ASSEMBLY

(a) Select a washer nozzle so that the washer fluid spray area is within the standard range. Replace the washer nozzle with the selected one.

Removal

REMOVAL

PROCEDURE

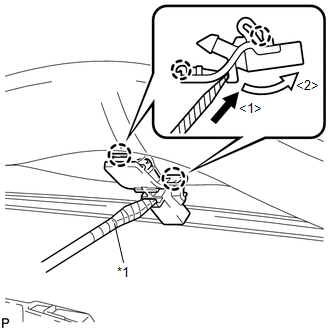

1. REMOVE FRONT WASHER NOZZLE SUB-ASSEMBLY

|

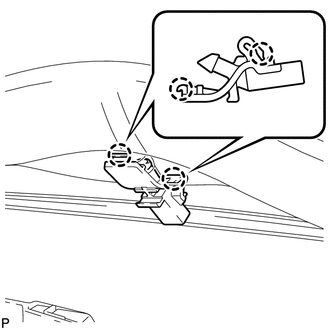

(a) Using a screwdriver, disengage the 2 claws and separate the washer nozzle sub-assembly as shown in the illustration. NOTICE: Be careful not to damage the windshield. HINT: Tape the screwdriver tip before use. Text in Illustration

|

|

|

(b) Remove the washer nozzle sub-assembly from the washer hose. NOTICE: Washer nozzles cannot be reused. |

|

Installation

INSTALLATION

PROCEDURE

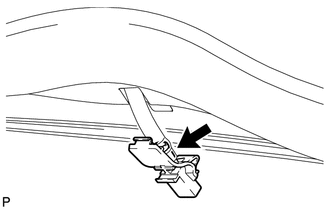

1. INSTALL FRONT WASHER NOZZLE SUB-ASSEMBLY

|

(a) Connect a new front washer nozzle sub-assembly to the washer hose. |

|

|

(b) Engage the 2 claws and install the front washer nozzle sub-assembly. |

|

2. INSPECT FRONT WASHER NOZZLE SUB-ASSEMBLY

.gif)

3. ADJUST FRONT WASHER NOZZLE SUB-ASSEMBLY

.gif)

Washer Motor(for Rear Side)

Washer Motor(for Rear Side)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER OUTSIDE MOULDING RH

HINT:

Use the same procedure for the RH side and LH side ...

Washer Nozzle(for Rear Side)

Washer Nozzle(for Rear Side)

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT REAR WASHER NOZZLE

(a) With the engine running, check where the washer fluid hits the w ...

Other materials about Toyota Venza:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL REAR AIRBAG SENSOR

(a) Check that the ignition switch is off.

(b) Check ...

Operation Check

OPERATION CHECK

1. CHECK POWER SEAT FUNCTION

(a) Check the basic functions.

Text in Illustration

*1

Slide Function

*2

Front Vertical Function

*3

Lifter Function

...

Front Blower Motor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

(a) Install the front blower motor sub-assembly with the 3 screws.

(b) Con ...

0.1234

.png)