Toyota Venza: Voice Recognition Microphone Disconnected (B1579)

DESCRIPTION

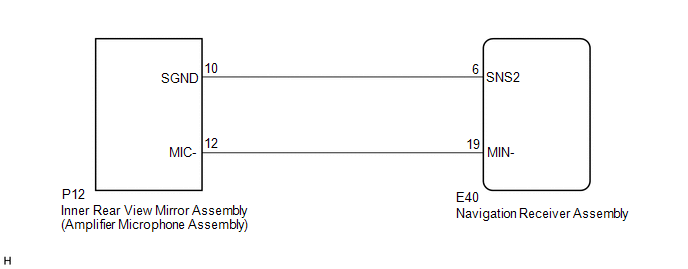

The navigation receiver assembly and inner rear view mirror assembly (amplifier microphone assembly) are connected to each other using the microphone connection detection signal lines.

This DTC is stored when a microphone connection detection signal line is disconnected.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1579 |

Telephone microphone signal is lost. |

|

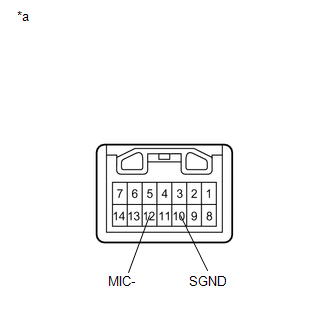

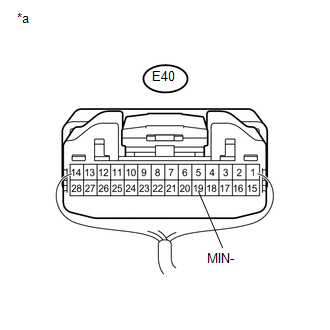

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT NAVIGATION RECEIVER ASSEMBLY |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (NAVIGATION RECEIVER ASSEMBLY - INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY)) |

(a) Disconnect the E40 navigation receiver assembly connector.

(b) Disconnect the P12 inner rear view mirror assembly (amplifier microphone assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

E40-6 (SNS2) - P12-10 (SGND) |

Always |

Below 1 Ω |

|

E40-19 (MIN-) - P12-12 (MIC-) |

Always |

Below 1 Ω |

|

E40-6 (SNS2) - Body ground |

Always |

10 kΩ or higher |

|

E40-19 (MIN-) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY) |

(a) Remove the inner rear view mirror assembly (amplifier microphone assembly)

(See page .gif) ).

).

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

| NG | .gif) |

REPLACE INNER REAR VIEW MIRROR ASSEMBLY (AMPLIFIER MICROPHONE ASSEMBLY) |

LVDS Signal Malfunction (from Extension Module) (B1532)

LVDS Signal Malfunction (from Extension Module) (B1532)

DESCRIPTION

The stereo component tuner assembly and the navigation receiver assembly are

connected by the LVDS communication line.

This DTC is stored when an LVDS communication error occurs betwee ...

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the CAN communication circuit.

DTC No.

DTC Detection Condition

Trouble Area

U0073

...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. USING TECHSTREAM

(a) Connect the Techstream to the DLC3.

(b) Monitor the ECU data by following the prompts on the Techstream screen.

HINT:

The Techstream has a "Snapshot" function which records the monitored data. Refe ...

Removal

REMOVAL

PROCEDURE

1. REMOVE WINDSHIELD WIPER MOTOR AND LINK

(a) Remove the windshield wiper motor and link (See page

).

2. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

3. REMOVE COOL AIR INTAKE DUCT SEAL

4. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

...

Throttle / Pedal Position Sensor "A" Minimum Stop Performance (P2109)

DESCRIPTION

The idle speed is controlled by the Electronic Throttle Control System (ETCS).

The ETCS is comprised of a throttle actuator, which operates the throttle valve,

and a throttle position sensor, which detects the opening amount of the throttle

...

0.114

.gif)