Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

4. REMOVE BATTERY

.gif)

5. REMOVE INLET AIR CLEANER ASSEMBLY

.gif)

6. REMOVE STARTER ASSEMBLY

|

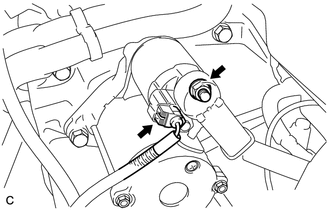

(a) Disconnect the starter connector. |

|

(b) Open the terminal cap, remove the nut and disconnect the starter wire.

|

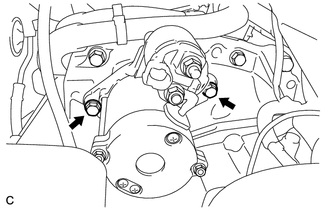

(c) Remove the 2 bolts and starter. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC SWITCH ASSEMBLY

(a) Remove the nut and disconnect the lead wire from the magnetic switch.

...

Other materials about Toyota Venza:

Noise Occurs or Sound Skips when Portable Player Plays

CAUTION / NOTICE / HINT

HINT:

Perform this check with the portable player volume set at an appropriate

level.

Make sure that there are no obstructions between the portable player

and the radio and display receiver assembly that may block ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL ATF TEMPERATURE SENSOR ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the ATF temperature

sensor assembly.

Text in Illustration

*1

O-ring

...

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

When Not Using the Engine Support Bridge: (See page

)

When Using the Engine Support Bridge: (See page

)

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for AWD)

When Not Using the Engine Supp ...

0.1191