Toyota Venza: Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HORN RELAY (ENGINE ROOM JUNCTION BLOCK ASSEMBLY)

|

(a) Remove the engine room junction block assembly from the engine room

relay block (See page |

|

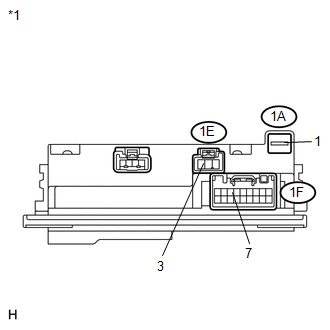

(b) Connect a positive (+) lead from the battery to terminal 1A-1.

(c) Connect a negative (-) lead from the battery to terminal 1F-7.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1E-3 - Battery negative |

Always |

11 to 14 V |

|

*1 |

Component without harness connected (Engine Room Junction Block Assembly) |

If the result is not as specified, replace the engine room junction block assembly.

Horn System

Horn System

Precaution

PRECAUTION

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

...

Lighting (ext)

Lighting (ext)

...

Other materials about Toyota Venza:

Inner Rear View Mirror Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the inner

rear view mirror assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the followin ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL LH

2. REMOVE FRONT FENDER OUTSIDE MOULDING LH

3. REMOVE FRONT FENDER LINER LH

(a) Using a screwdriver, turn the pin 90 degrees and remove the 2 pin

hold clips.

Text in Illustration

...

Engine does not Start

DESCRIPTION

1. ENGINE START SYSTEM FUNCTION

(a) If the engine switch is pressed with the shift lever in P or N and the brake

pedal depressed, the power management control ECU determines that this is an engine

start request.

(b) The certification ECU (sm ...

0.1271

.gif) ).

).