Toyota Venza: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use high-temperature grease to lubricate the bearings, gears and return spring when assembling the starter.

PROCEDURE

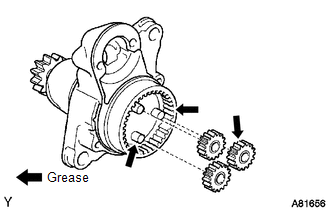

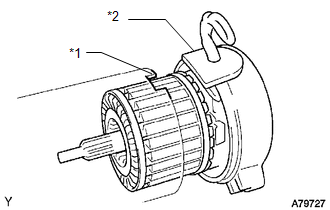

1. INSTALL PLANETARY GEAR

|

(a) Apply grease to the planetary gears and pin parts of the planetary shaft. |

|

(b) Install the 3 planetary gears.

2. INSTALL STARTER ARMATURE ASSEMBLY

(a) Apply grease to the plate washer and the armature shaft.

NOTICE:

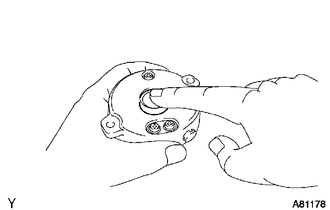

- Be sure to install the snap ring in the armature shaft groove securely.

- Be sure to properly install the snap ring because it expands easily.

(b) Install the starter armature to the starter commutator end frame.

|

(c) Using snap ring pliers, install the plate washer and a new snap ring. Text in Illustration

|

|

|

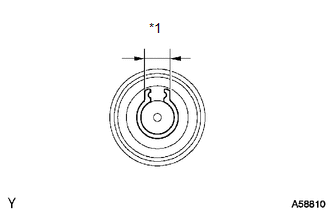

(d) Using a vernier caliper, measure the length of the snap ring. Text in Illustration

Maximum length: 5.0 mm (0.196 in.) If the length is greater than the maximum, replace it with a new snap ring. |

|

3. INSTALL STARTER COMMUTATOR END FRAME COVER

|

(a) Install the end frame cover to the commutator end frame. |

|

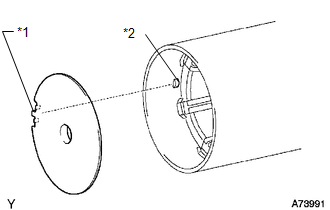

4. INSTALL STARTER ARMATURE PLATE

|

(a) Insert the starter armature plate to the starter yoke. Text in Illustration

|

|

(b) Align the keyway of the starter armature plate with the key inside the starter yoke, and install the starter armature plate.

5. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

|

(a) Align the rubber of the end frame with the cutout of the starter yoke. Text in Illustration

|

|

(b) Install the end frame to the starter yoke.

NOTICE:

The magnet of the starter yoke may attract the starter armature when the starter commutator end frame is installed, causing the magnet to break.

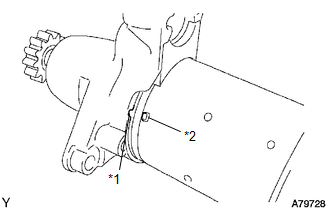

6. INSTALL STARTER YOKE ASSEMBLY

|

(a) Align the protrusion of the starter yoke with the cutout of the starter drive housing. Text in Illustration

|

|

|

(b) Install the starter yoke with the 2 through-bolts. Torque: 6.0 N·m {61 kgf·cm, 53 in·lbf} |

|

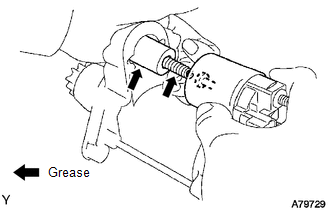

7. INSTALL MAGNETIC SWITCH ASSEMBLY

|

(a) Apply grease to the plunger and the hook. |

|

(b) Hang the plunger hook of the magnetic switch to the drive lever.

(c) Install the plunger and return spring.

|

(d) Install the magnetic switch with the 2 screws. Torque: 7.5 N·m {76 kgf·cm, 66 in·lbf} |

|

|

(e) Connect the lead wire to the magnetic switch with the nut. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT STARTER ASSEMBLY

NOTICE:

These tests must be performed within 3 to 5 seconds to avoid burning out the

coil.

(a) Perform a pull-in test.

(1) Remove the nut and d ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque:

37 N·m {377 kgf·cm, 27 ft·lbf}

...

Other materials about Toyota Venza:

System Description

SYSTEM DESCRIPTION

1. POWER MIRROR CONTROL SYSTEM DESCRIPTION

(a) This system has the following functions: power retract mirror function*,

reverse shift-linked function, electrical remote control function, memory function

and mirror heater function.

...

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DOOR BELT MOULDING

(a) Engage the 5 claws to install the front door belt moulding.

(b) Install the clip.

2. INSTALL FRONT DOOR GLASS RUN

3. INSTALL FRONT ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE UPPER BACK WINDOW PANEL TRIM

(a) Disengage the 4 clips and 4 claws, and remove the upper back window

panel trim.

2. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

...

0.1717

.png)

.png)

.png)

.png)