Toyota Venza: Rear Wheel Alignment

Adjustment

ADJUSTMENT

PROCEDURE

1. INSPECT TIRES

(a) Inspect the tires (See page .gif) ).

).

2. MEASURE VEHICLE HEIGHT

.gif)

3. INSPECT CAMBER

Camber (Unloaded Vehicle):

|

Model |

Engine |

Camber Inclination |

Right-left Difference |

|---|---|---|---|

|

2WD |

1AR-FE |

-1°13' +/- 45' (-1.22° +/- 0.75°) |

45' (0.75°) or less |

|

2GR-FE |

-1°14' +/- 45' (-1.23° +/- 0.75°) |

||

|

AWD |

1AR-FE |

-0°47' +/- 45' (-0.78° +/- 0.75°) |

|

|

2GR-FE |

-0°48' +/- 45' (-0.80° +/- 0.75°) |

HINT:

Camber is not adjustable. If the measurement is not within the specified range, inspect the suspension parts for damage and/or wear, and replace them if necessary.

4. INSPECT TOE-IN

Toe-in (Unloaded Vehicle):

|

Model |

Specified Condition |

Right-left Difference |

|---|---|---|

|

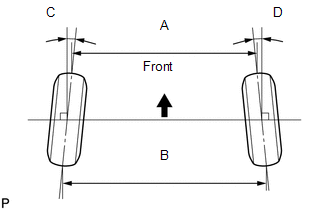

2WD |

C + D: 0°17' +/- 0°10' (0.28° +/- 0.16°) |

30' (0.50°) or less |

|

B - A: 3.8 +/- 2.0 mm (0.150 +/- 0.0787 in.) |

- |

|

|

AWD |

C + D: 0°16' +/- 0°10' (0.27° +/- 0.16°) |

30' (0.50°) or less |

|

B - A: 3.6 +/- 2.0 mm (0.142 +/- 0.0787 in.) |

- |

If the toe-in is not within the specified range, adjust it at the rear No. 2 suspension arms.

HINT:

Measure "B - A" only when "C + D" cannot be measured.

5. ADJUST TOE-IN (for 2WD)

|

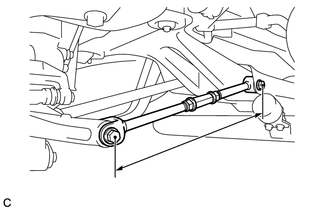

(a) Measure the lengths of the right and left rear No. 2 suspension arms. Difference in the length of rear No. 2 suspension arms: 1.5 mm (0.0590 in.) or less If the left-right difference is larger than 1.5 mm (0.0590 in.), adjust it by following the procedures below. |

|

|

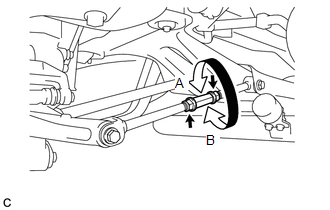

(b) Loosen the 2 lock nuts. |

|

(c) If the length difference between the left and right rear No. 2 suspension arm assemblies is not within the specified range, adjust it by following the procedures below.

(1) If the toe-in measurement is greater than the specified range, extend the shorter rear No. 2 suspension arm assembly by rotating the adjusting tube in the direction of arrow B in the illustration.

(2) If the toe-in measurement is less than the specified range, shorten the longer rear No. 2 suspension arm assembly by rotating the adjusting tube in the direction of arrow A in the illustration.

(3) Measure the toe-in.

(d) Turn the right and left adjusting tubes by an equal amount to adjust toe-in.

HINT:

- Try to adjust the toe-in to the center of the specified range.

- One turn of each adjusting tube will adjust the toe-in by approximately 11.1 mm (0.437 in.).

(e) Tighten the lock nuts while securing the adjusting tube in the order indicated below:

Torque:

56 N·m {571 kgf·cm, 41 ft·lbf}

- Tighten the outside lock nut.

- Tighten the inside lock nut.

- Retighten the outside lock nut.

6. ADJUST TOE-IN (for AWD)

(a) Measure the distance between each wheel disc and the center of the toe-adjusting cam.

Difference in the distance between each wheel disc and the center of the toe-adjusting cam:

1.0 mm (0.0393 in.) or less

If the left-right difference is larger than 1.0 mm (0.0393 in.), adjust it by following the procedures below.

|

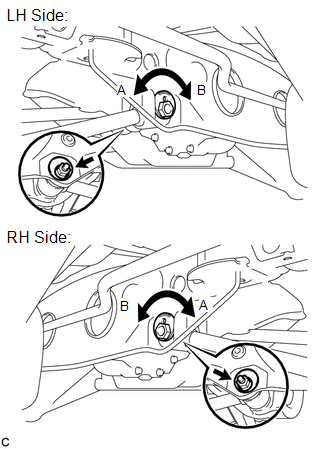

(b) Loosen the toe-adjust cam set nuts. |

|

(c) If the distance between each wheel disc and the center of the toe-adjusting cam is not within the specified range, adjust it by following the procedures below.

(1) If the toe-in measurement is greater than the specified range, extend the shorter rear No. 2 suspension arm assembly by rotating the adjust cams in the direction of arrow B in the illustration.

(2) If the toe-in measurement is less than the specified range, shorten the longer rear No. 2 suspension arm assembly by rotating the adjust cams in the direction of arrow A in the illustration.

(3) Measure the toe-in.

(d) Turn the adjust cams by an equal amount to adjust toe-in.

HINT:

- Try to adjust the toe-in to the center of the specified range.

- One graduation of each adjusting cam will adjust the toe-in by approximately 3.3 mm (0.130 in.).

(e) Tighten the toe-adjust cam set nuts.

Torque:

100 N·m {1020 kgf·cm, 74 ft·lbf}

NOTICE:

The final torque must be applied under standard vehicle height conditions.

Adjustment

Adjustment

ADJUSTMENT

PROCEDURE

1. INSPECT TIRES

(a) Inspect the tires (See page ).

2. MEASURE VEHICLE HEIGHT

NOTICE:

Before inspecting the wheel alignment, adjust the vehicle height to

the sp ...

Front Suspension

Front Suspension

...

Other materials about Toyota Venza:

Engine Stall History (P1603,P1605)

DESCRIPTION

P1603

After starting the engine, this DTC is stored when the engine stops without the

ignition switch being operated.

Using the Techstream, the conditions present when the DTC was stored can be confirmed

by referring to the freeze frame data ...

Garage Door Opener Switch

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE ROOF CONSOLE BOX ASSEMBLY (GARAGE DOOR OPENER SWITCH)

(a) Using a moulding remover, disengage the 2 claws and 2 clips.

Text in Illustration

*1 ...

Terminals Of Ecu

TERMINALS OF ECU

1. CHECK POSITION CONTROL ECU AND SWITCH ASSEMBLY

(a) Disconnect the T10 and T11 position control ECU and switch assembly connectors.

(b) Measure the voltage and resistance according to the value(s) in the table

below.

HINT:

Measure t ...

0.1341