Toyota Venza: Power Back Door Warning System does not Operate

DESCRIPTION

When the power back door warning system does not operate, one of the following may be malfunctioning: 1) power back door warning buzzer circuit, 2) wireless door lock control system or 3) power back door ECU.

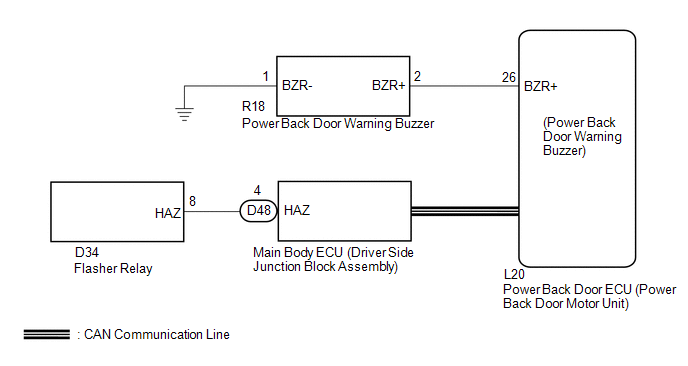

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The power back door warning function can be customized. Make sure the

function is ON. (See page

.gif) )

)

- The power back door system uses a CAN communication system. Inspect

the communication function by following How to Proceed with Troubleshooting

(See page

.gif) ). Troubleshoot the power back

). Troubleshoot the power back

door system after confirming that the communication system is functioning properly.

PROCEDURE

|

1. |

CHECK OPERATION |

(a) Check power back door system operation.

|

Result |

Proceed to |

|---|---|

|

Power back door warning buzzer does not operate |

A |

|

Hazard warning light does not come on |

B |

|

Power back door warning buzzer in the power back door ECU does not operate |

C |

| B | .gif) |

GO TO STEP 5 |

| C | .gif) |

REPLACE POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM (POWER BACK DOOR WARNING BUZZER) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Back Door / Data List.

(e) Using the Techstream, perform the Active Test to generate a control command, and check that the power back door warning buzzer sounds.

Back Door (Power Back Door ECU)|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

PBD Buzzer |

Power back door warning buzzer sound |

ON / OFF |

- |

OK:

Buzzer sounds normally.

| OK | .gif) |

REPLACE POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) |

|

|

3. |

INSPECT POWER BACK DOOR WARNING BUZZER |

|

(a) Remove the power back door warning buzzer (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (BZR+) - 1(BZR-) |

Always |

950 to 1050 Ω |

|

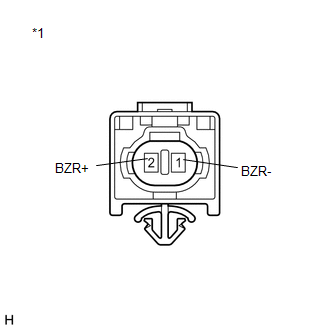

*1 |

Component without harness connected (Power Back Door Warning Buzzer) |

| NG | .gif) |

REPLACE POWER BACK DOOR WARNING BUZZER |

|

|

4. |

CHECK HARNESS AND CONNECTOR (POWER BACK DOOR WARNING BUZZER - POWER BACK DOOR ECU) |

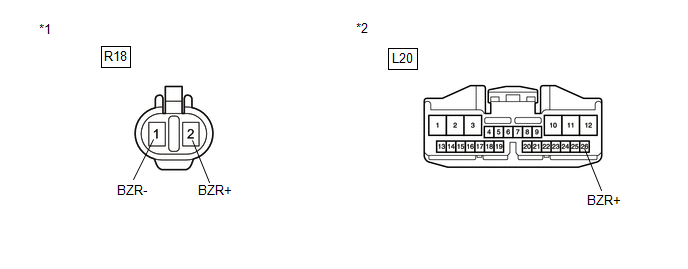

(a) Disconnect the R18 power back door warning buzzer connector and L20 power back door ECU connector.

(b) Disconnect the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R18-2 (BZR+) - L20-26 (BZR+) |

Always |

Below 1 Ω |

|

R18-1 (BZR-) - Body ground |

Always |

Below 1 Ω |

|

R18-2 (BZR+) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Back Door Warning Buzzer) |

|

*2 |

Front view of wire harness connector (to Power Back Door ECU) |

| OK | .gif) |

REPLACE POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

5. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM (HAZARD ANSWER-BACK FUNCTION) |

(a) Check wireless door lock operation.

|

Result |

Proceed to |

|---|---|

|

Hazard answer-back function operates normally |

A |

|

Hazard answer-back function does not operate (w/ Smart Key System) |

B |

|

Hazard answer-back function does not operate (w/o Smart Key System) |

C |

| B | .gif) |

GO TO WIRELESS DOOR LOCK CONTROL SYSTEM (w/ Smart Key System) (NO ANSWER-BACK) |

| C | .gif) |

GO TO WIRELESS DOOR LOCK CONTROL SYSTEM (w/o Smart Key System) (NO ANSWER-BACK) |

|

|

6. |

REPLACE POWER BACK DOOR MOTOR UNIT (POWER BACK DOOR ECU) |

(a) Replace the power back door ECU (power back door motor unit) (See page

.gif) ).

).

|

|

7. |

CHECK POWER BACK DOOR OPERATION |

(a) Check that the power back door hazard warning lights operate normally (See

page .gif) ).

).

OK:

The power back door hazard warning lights operate normally.

| OK | .gif) |

END (POWER BACK DOOR ECU (POWER BACK DOOR MOTOR UNIT) WAS DEFECTIVE) |

| NG | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

Jam Protection Function Activates During Power Back Door Operation

Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

When the jam protection function activates during power back door operation,

one of the following may be the cause: 1) improper fit of back door, or a foreign

object is stuck in the b ...

Touch Sensor Circuit

Touch Sensor Circuit

DESCRIPTION

When the power back door ECU receives a jam signal from the touch sensor while

the power back door is operating, the ECU reverses the back door operation and opens

the door.

WIRING D ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR DRIVE SHAFT ASSEMBLY

(a) Align the shaft splines and install the rear drive shaft assembly

using a screwdriver and hammer.

NOTICE:

Set the snap ring with the opening facing downward.

...

Installation

INSTALLATION

PROCEDURE

1. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

(a) Using a T30 "TORX" socket wrench, install the windshield wiper motor

assembly with the 2 bolts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

...

Panel Switches do not Function

PROCEDURE

1.

CHECK PANEL SWITCH

(a) Check for foreign matter around the switches that might prevent operation.

OK:

No foreign matter is found.

NG

REMOVE ANY FOREIGN MATTER FOUND

...

0.18

.gif)