Toyota Venza: Power Back Door Main Switch

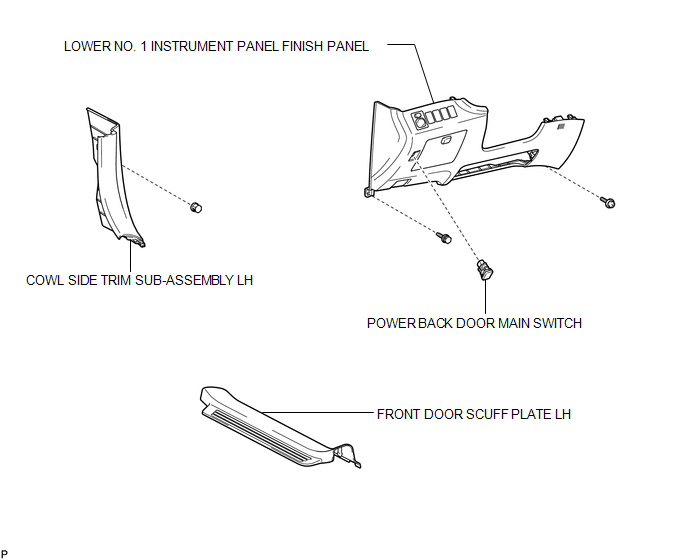

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

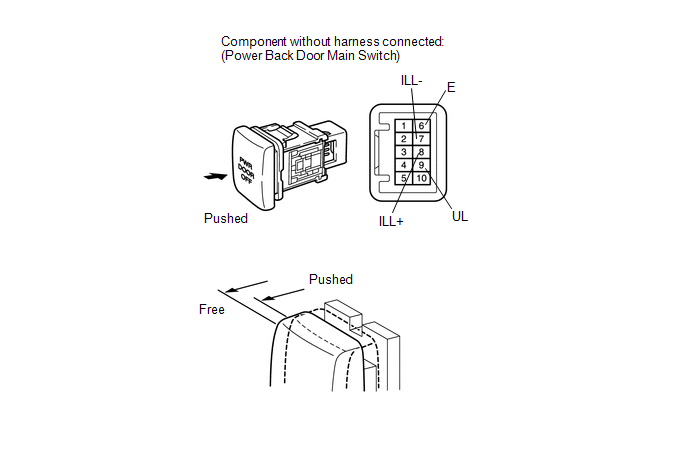

1. INSPECT POWER BACK DOOR MAIN SWITCH

(a) Check that the switch function.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

6 (E) - 9 (UL) |

Free |

Below 1 Ω |

|

6 (E) - 9 (UL) |

Pushed |

10 kΩ or higher |

If the result is not as specified, replace the switch.

(b) Check that the switch illuminates.

(1) Apply battery voltage to the power back door main switch and check that the switch illuminates.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → 8 (ILL+) Battery negative (-) → 7 (ILL-) |

Illuminates |

If the result is not as specified, replace the switch.

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT DOOR SCUFF PLATE LH

.gif)

2. REMOVE COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

3. REMOVE LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

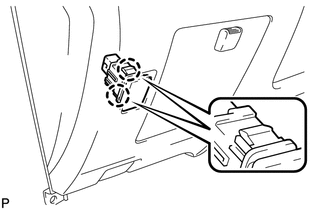

4. REMOVE POWER BACK DOOR MAIN SWITCH

|

(a) Disengage the 2 claws and remove the power back door main switch. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER BACK DOOR MAIN SWITCH

|

(a) Engage the 2 claws and install the power back door main switch. |

|

2. INSTALL LOWER NO. 1 INSTRUMENT PANEL FINISH PANEL

.gif)

3. INSTALL COWL SIDE TRIM SUB-ASSEMBLY LH

.gif)

4. INSTALL FRONT DOOR SCUFF PLATE LH

.gif)

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER BACK DOOR UNIT ASSEMBLY

(a) Install the power back door unit with the 4 bolts.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

...

Other materials about Toyota Venza:

Tires

Replace or rotate tires in accordance with maintenance schedules and treadwear.

- Checking tires

1. New tread

2. Treadwear indicator

3. Worn tread

The location of treadwear indicators is shown by the “TWI” or “Δ” marks, etc.,

molded ...

Locking the driver’s doors from the outside without a key

Move the inside lock button to the

lock position.

Close the door.

►Vehicles with smart key system

The door cannot be locked if the “ENGINE START STOP” switch is in ACCESSORY or IGNITION

ON mode, or the electronic key is left inside the vehic ...

Dtc Check / Clear

DTC CHECK / CLEAR

1. DTC CHECK/CLEAR (USING TECHSTREAM)

(a) CHECK DTC

(1) Connect the Techstream to the DLC3.

(2) Turn the ignition switch on (IG).

(3) Read the DTC by following the prompts on the Techstream screen.

HINT:

Refer to the Techstream operato ...

0.1561

.png)