Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK BATTERY CONDITION

NOTICE:

If the battery is weak or if the engine is difficult to start, perform the following procedure.

(a) Check the battery for damage or deformation. If severe damage, deformation or leakage is found, replace the battery.

(b) Check the electrolyte quantity of each cell.

|

(1) For maintenance-free batteries:

|

|

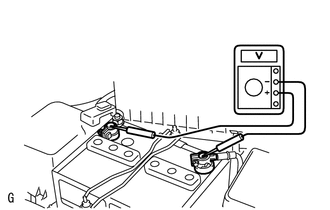

(c) Check the voltage.

(1) Turn the ignition switch off and turn on the headlights for 20 to 30 seconds. This will remove the surface charge from the battery.

(2) Measure the battery voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Positive (+) terminal - Negative (-) terminal |

20°C (68°F) |

12.5 to 12.9 V |

If the result is not as specified, recharge or replace the battery.

2. INSPECT BATTERY TERMINAL

(a) Check that the battery terminals are not loose or corroded.

If a terminal is loose or corroded, tighten or clean the terminal.

Torque:

Positive (+) Battery Terminal :

6.9 N·m {70 kgf·cm, 61 in·lbf}

Negative (-) Battery Terminal :

6.9 N·m {70 kgf·cm, 61 in·lbf}

3. INSPECT FUSES

(a) Measure the resistance of each fuse for the charging system.

HINT:

The fuses shown in the System Diagram are related to the charging system.

Standard Resistance:

Below 1 Ω

- If any of the results is not as specified, replace the fuse(s) as necessary.

4. INSPECT V-RIBBED BELT

.gif)

5. INSPECT GENERATOR WIRING

(a) Visually check the generator wiring.

(1) Check that the wiring is in good condition.

6. CHECK FOR ABNORMAL NOISES

(a) Listen for abnormal noises from the generator.

(1) Check that no abnormal noises are heard from the generator while the engine is running.

7. INSPECT CHARGE WARNING LIGHT CIRCUIT

(a) Turn the ignition switch to ON. Check that the charge warning light comes on.

(b) Start the engine and check that the light goes off.

If the light does not operate as specified, troubleshoot the charge warning light circuit.

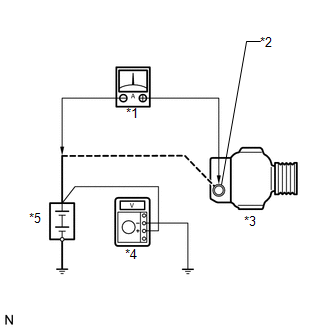

8. INSPECT CHARGING CIRCUIT WITHOUT LOAD

|

(a) Connect a voltmeter and ammeter to the charging circuit as follows. Text in Illustration

(1) Disconnect the wire from terminal B of the generator, and then connect it to the negative (-) lead of the ammeter. (2) Connect the positive (+) lead of the ammeter to terminal B of the generator. (3) Connect the positive (+) lead of the voltmeter to the positive (+) terminal of the battery. (4) Ground the negative (-) lead of the voltmeter. |

|

(b) Check the charging circuit.

(1) Keep the engine speed at 2000 rpm and check the reading on the ammeter and voltmeter.

Standard Current:

10 A or less

Standard Voltage:

13.2 to 14.8 V

If the result is not as specified, repair or replace the generator.

HINT:

If the battery is not fully charged, the ammeter reading will sometimes be more than the standard amperage.

9. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2000 rpm, turn the high beam headlights on and turn the heater blower switch to the "HI" position.

(b) Check the reading on the ammeter.

Standard Current:

30 A or more

If the ammeter reading is less than the standard amperage, repair or replace the generator.

HINT:

If the battery is fully charged, the indication will sometimes be less than the standard amperage. If this is the case, add more electrical load (operate the wipers, rear window defogger, etc.) and check the reading on the ammeter again.

System Diagram

System Diagram

SYSTEM DIAGRAM

...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in o ...

Other materials about Toyota Venza:

Evaporative Emission Control System Incorrect Purge Flow (P0441)

DTC SUMMARY

DTC No.

Monitoring Item

Malfunction Detection Condition

Trouble Area

Detection Timing

Detection Logic

P0441

Purge VSV (Vacuum Switching Valve) stuck open ...

Check CAN Bus Lines for Short Circuit

DESCRIPTION

There may be a short circuit in the CAN bus main wire and/or CAN branch wire

when the resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3 is below

54 Ω.

Symptom

Trouble Area

Resistance betwe ...

Back Door Support

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR STAY ASSEMBLY

NOTICE:

Avoid touching the piston rod as much as possible to prevent foreign

matter from attaching to it. Be sure to hold the cylinder whil ...

0.152