Toyota Venza: Oil Pressure Switch

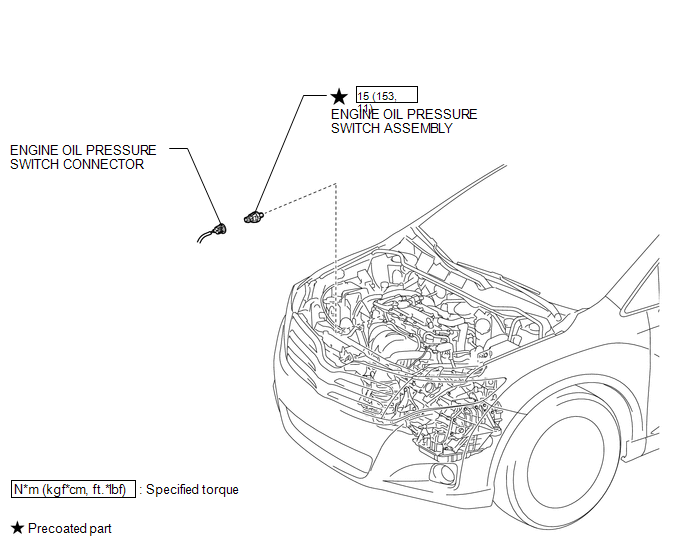

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

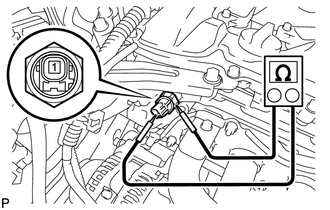

1. INSPECT ENGINE OIL PRESSURE SWITCH ASSEMBLY

(a) Disconnect the oil pressure switch connector.

(b) Start the engine.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the oil pressure switch assembly. |

|

Removal

REMOVAL

PROCEDURE

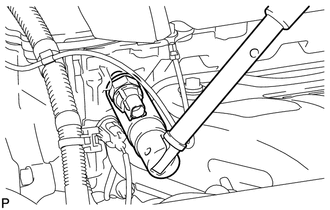

1. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

|

(a) Disconnect the oil pressure switch connector. |

|

(b) Using a 24 mm deep socket wrench, remove the oil pressure switch.

Installation

INSTALLATION

PROCEDURE

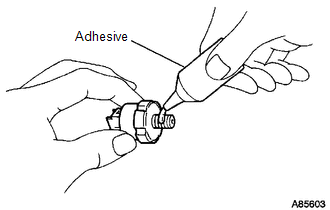

1. INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY

|

(a) Apply adhesive to 2 or 3 threads of the oil pressure switch. Adhesive: TOYOTA Genuine Adhesive 1344, Three Bond 1344 or equivalent. NOTICE: Do not let adhesive adhere to the oil hole. |

|

|

(b) Using a 24 mm deep socket wrench, install the oil pressure switch. Torque: 15 N·m {153 kgf·cm, 11 ft·lbf} NOTICE: Do not start the engine within 1 hour of installation. |

|

(c) Connect the oil pressure switch connector.

2. INSPECT FOR OIL LEAK

.gif)

3. INSPECT ENGINE OIL LEVEL

.gif)

Replacement

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

Prolonged and repeated contact with engine oil will result in the removal

of natural oils from the skin, leading to dryness, irritation and ...

Oil Pump

Oil Pump

...

Other materials about Toyota Venza:

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the

National Highway Traffic Safety Administration of the U.S. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota vehicles with

infor ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is output during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to "See page" in the DTC chart.

Inspect the fuses and relays before troub ...

Driving position memory

Your preferred driving position (the position of the driver’s seat and angle

of the outside rear view mirrors) can be memorized and recalled by pressing a button.

It is also possible to set this function to activate automatically when the doors

are unl ...

0.1313

.png)