Toyota Venza: Monitor Drive Pattern

MONITOR DRIVE PATTERN

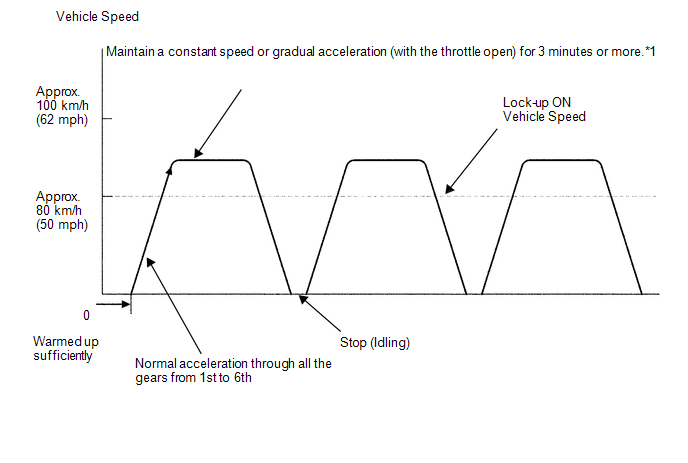

1. TEST MONITOR DRIVE PATTERN FOR ECT

CAUTION:

Perform this drive pattern on a level surface and strictly observe the posted speed limits and traffic laws while driving.

HINT:

Performing this drive pattern is one method to simulate the TCM (ECT) malfunction detection conditions.

Some DTCs may not be detected through ordinary, everyday driving. Also, DTCs may not be detected through this drive pattern.

(a) Preparation for driving

(1) Warm up the engine sufficiently (engine coolant temperature is 60°C (140°F) or higher).

(2) Drive the vehicle when the atmospheric temperature is -10°C (14°F) or higher.

Some malfunctions are not detected when the atmospheric temperature is less than -10°C (14°F).

(b) Drive pattern

(1) Drive the vehicle through all the gears.

Stop → 1st → 2nd → 3rd → 4th → 5th → 6th → 6th (lock-up ON).

(2) Confirm engine braking using the S position. While driving with S6 range selected and 6th gear operating with lock-up on, move the shift lever toward "-" to downshift from 6 to 5, 5 to 4, 4 to 3, 3 to 2, 2 to 1.

(3) Repeat the above drive pattern three times or more.

NOTICE:

- When using the Techstream, the monitor status can be checked in the

Data List (See page

.gif) ).

). - In the event that the drive pattern must be interrupted (due to traffic conditions or other factors), the drive pattern can be resumed and, in most cases, the monitor can be completed.

HINT:

*1: Drive the vehicle at a speed in top gear that will cause lock-up to engage. The vehicle can be driven at a speed lower than that in the above diagram under the lock-up condition.

NOTICE:

It is necessary to drive the vehicle for approximately 30 minutes to detect DTC P0711 (ATF temperature sensor malfunction).

Initialization

Initialization

INITIALIZATION

1. RESET TRANSAXLE COMPENSATION CODE

NOTICE:

If the following parts have been replaced, initialize the TCM and perform

the following "Reset Memory" and "Pe ...

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are lis ...

Other materials about Toyota Venza:

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) The power back door ECU (power back door motor unit)*1 or back door closer

ECU (multiplex network door ECU)*2 controls the vehicle's back door closer system

functions. Back door closer system data and Diagnostic Tr ...

Front Wiper Rubber

Components

COMPONENTS

ILLUSTRATION

Replacement

REPLACEMENT

PROCEDURE

1. REMOVE FRONT WIPER BLADE

(a) Remove the holder of the front wiper blade.

(b) Remove the front wiper blade from the f ...

Vehicle Speed Sensor Malfunction (B2415)

DESCRIPTION

The AFS ECU (headlight swivel ECU assembly) receives signals indicating the front

right wheel speed from the skid control ECU using CAN communication.

DTC No.

DTC Detection Condition

Trouble Area

...

0.1574