Toyota Venza: LVL Terminal Circuit

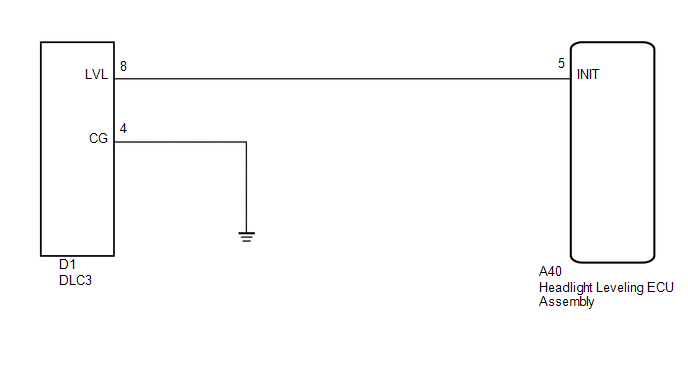

DESCRIPTION

- By connecting terminals LVL and CG of the DLC3, the headlight leveling ECU assembly initializes the height control sensor signal.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (DLC3 - HEADLIGHT LEVELING ECU ASSEMBLY) |

|

(a) Disconnect the A40 headlight leveling ECU assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A40-5 (INIT) - D1-8 (LVL) |

Always |

Below 1 Ω |

|

A40-5 (INIT) - Body ground |

Always |

10 kΩ or higher |

|

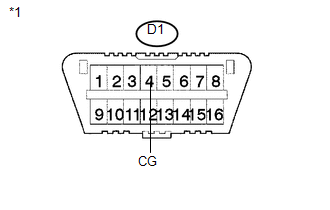

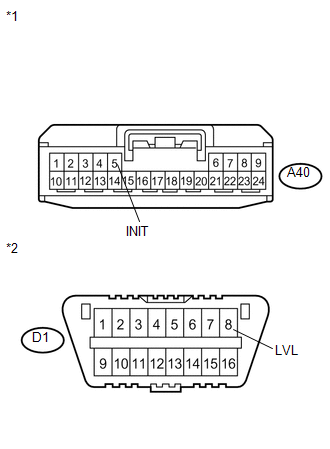

*1 |

Front view of wire harness connector (to Headlight Leveling ECU Assembly) |

|

*2 |

DLC3 |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (DLC3 - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Inner Rear View Mirror Power Source Circuit

Inner Rear View Mirror Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the inner

rear view mirror assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for ci ...

Diagnosis Circuit

Diagnosis Circuit

DESCRIPTION

The headlight leveling ECU assembly outputs DTC information to the Techstream

via this circuit.

WIRING DIAGRAM

PROCEDURE

1.

CHECK HARNESS AND CONNECTOR (DLC3 ...

Other materials about Toyota Venza:

Check CAN Bus Line for Short to +B

DESCRIPTION

There may be a short circuit between the CAN bus main wire and +B when no resistance

exists between terminals 6 (CANH) and 16 (BAT) or 14 (CANL) and 16 (BAT) of the

DLC3.

Symptom

Trouble Area

No resistan ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure is for the LH side.

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE (for 2GR-FE)

HINT:

Refer to the procedure up to Re ...

Front Passenger Seat Belt Warning Light

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL ACCESSORY METER ASSEMBLY (w/o Rear View Monitor System)

(a) Connect the connector.

(b) Engage the 2 clamps.

(c) Engage the 2 clips.

(d) Install the accessory mete ...

0.1478

.gif)