Toyota Venza: Lost Communication with AFS LIN (B124D)

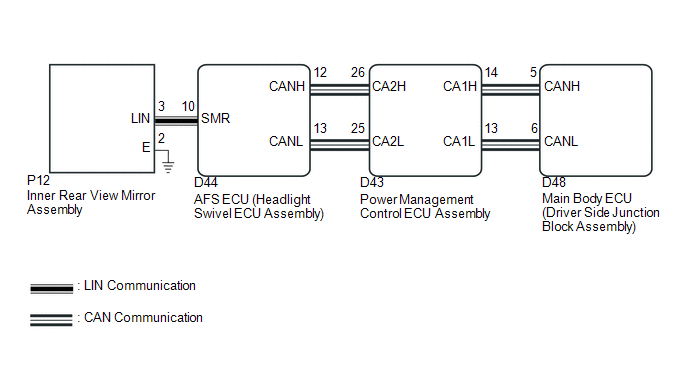

DESCRIPTION

The DTC is stored when the main body ECU (driver side junction block assembly) detects malfunctions in the LIN communication system.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B124D |

Malfunction in LIN communication system |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

First perform the communication function inspections in How to Proceed with Troubleshooting to confirm that there are no CAN communication malfunctions before troubleshooting this symptom.

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Clear the DTCs (See page .gif) ).

).

(b) Check for DTCs (See page .gif) ).

).

OK:

DTC B124D is not output.

| OK | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

2. |

CHECK HARNESS AND CONNECTOR (AFS ECU - INNER REAR VIEW MIRROR ASSEMBLY) |

(a) Disconnect the D44 AFS ECU (headlight swivel ECU assembly) connector.

(b) Disconnect the P12 inner rear view mirror assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D44-10 (SMR) - P12-3 (LIN) |

Always |

Below 1 Ω |

|

P12-3 (LIN) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT AFS ECU (HEADLIGHT SWIVEL ECU ASSEMBLY) |

(a) Reconnect the D44 AFS ECU (headlight swivel ECU assembly) connector.

|

(b) Connect an oscilloscope to the P12 inner rear view mirror assembly connector. |

|

|

(c) Check the waveform. OK:

|

|

| OK | .gif) |

REPLACE INNER REAR VIEW MIRROR ASSEMBLY |

| NG | .gif) |

REPLACE AFS ECU (HEADLIGHT SWIVEL ECU ASSEMBLY) |

Automatic High Beam Camera (B124C)

Automatic High Beam Camera (B124C)

DESCRIPTION

The DTC is stored when the main body ECU (driver side junction block assembly)

detects malfunctions in the camera (inner rear view mirror assembly).

DTC No.

DTC D ...

Steering Position Sensor Malfunction (B2414)

Steering Position Sensor Malfunction (B2414)

DESCRIPTION

The AFS ECU (headlight swivel ECU assembly) receives signals indicating the swerve-angle

from the steering angle sensor using CAN communication.

DTC No.

DTC Detec ...

Other materials about Toyota Venza:

Back Door Entry Lock Function does not Operate

DESCRIPTION

If the back door entry lock function does not operate but the back door open

function operates, the communication between the vehicle and key is normal. As a

faulty part, the entry lock switch circuit (from the back door opener switch assembly ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is stored during the DTC check, inspect the trouble areas listed

for that code. For details of the code, refer to the "See page" below.

Main Body

DTC Code

Detection Ite ...

0.1201

.gif)

.png)

.png)