Toyota Venza: Installation

INSTALLATION

PROCEDURE

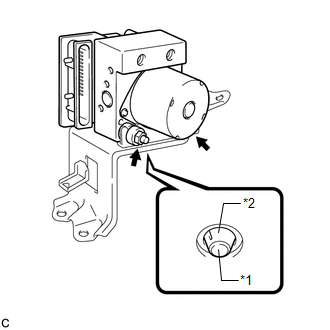

1. INSTALL BRAKE ACTUATOR ASSEMBLY

|

(a) Install the brake actuator assembly to the brake actuator bracket assembly with the 2 nuts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} NOTICE:

|

|

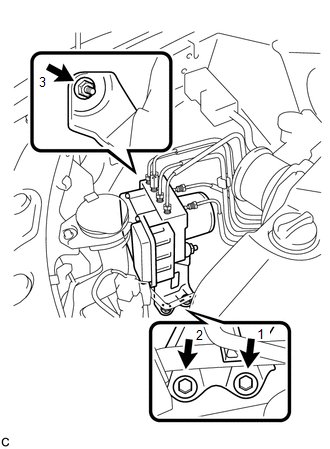

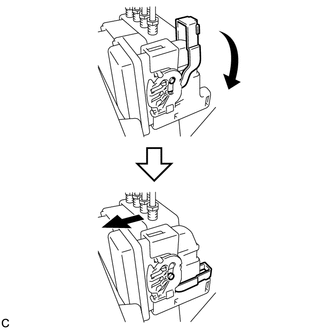

2. INSTALL BRAKE ACTUATOR WITH BRACKET

|

(a) Install the brake actuator with bracket to the body with the nut and 2 bolts. Torque: 19 N·m {194 kgf·cm, 14 ft·lbf} NOTICE:

|

|

|

(b) Connect the brake actuator connector. NOTICE:

|

|

|

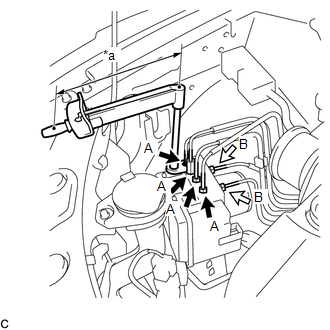

(c) Temporarily tighten each brake line to the correct positions of the brake actuator with bracket as shown in the illustration. Text in Illustration

|

|

(d) Using a union nut wrench, fully tighten 4 brake lines (A).

Text in Illustration

Text in Illustration

|

*a |

Torque Wrench Fulcrum Length |

|

Flare Nut A (10 mm) |

.png) |

Flare Nut B (12 mm) |

Torque:

Specified Tightening Torque :

15 N·m {155 kgf·cm, 11 ft·lbf}

HINT:

- Calculate the torque wrench reading when changing the fulcrum length

for the torque wrench (See page

.gif) ).

).

- When using a union nut wrench (fulcrum length of 22 mm (0.866 in.))

+ torque wrench (fulcrum length of 250 mm (9.84 in.)):

14 N*m (142 kgf*cm, 10 ft.*lbf)

(e) Using a union nut wrench, fully tighten 2 brake lines (B).

Torque:

Specified Tightening Torque :

20 N·m {199 kgf·cm, 14 ft·lbf}

HINT:

- Calculate the torque wrench reading when changing the fulcrum length

for the torque wrench (See page

.gif) ).

).

- When using a union nut wrench (fulcrum length of 20 mm (0.787 in.))

+ torque wrench (fulcrum length of 250 mm (9.84 in.)):

18 N*m (184 kgf*cm, 13 ft.*lbf)

|

(f) Install the clamp of the suction hose sub-assembly to the brake actuator bracket assembly. |

|

3. INSTALL RADIATOR RESERVE TANK ASSEMBLY

|

(a) Install the radiator reserve tank assembly. |

|

(b) Install the radiator reserve tank cap assembly.

4. FILL RESERVOIR WITH BRAKE FLUID

.gif)

5. BLEED BRAKE MASTER CYLINDER

.gif)

6. BLEED BRAKE LINE

.gif)

7. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

8. INSPECT FOR BRAKE FLUID LEAK

9. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

10. PERFORM ENGINE VARIANT LEARNING

(See page .gif) )

)

11. INSPECT BRAKE ACTUATOR USING TECHSTREAM

(See page .gif) )

)

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Brake Pedal Load Sensing Switch

Brake Pedal Load Sensing Switch

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE PEDAL LOAD SENSING SWITCH

NOTICE:

Do not remove the brake pedal load sensing switch from the brake pedal

suppo ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system.

NOTICE:

When disconnecting the cable, some systems ne ...

Power Mirrors do not Return to Memorized Position

SYSTEM DESCRIPTION

If either the M1 or M2 seat memory switch is pressed, the outer mirror control

ECU assembly (driver door) detects the seat memory switch status and sends the switch

signal to the main body ECU (driver side junction block assembly) via C ...

If you have a flat tire

Remove the flat tire and replace it with the spare provided. - Before

jacking up the vehicle

• Stop the vehicle on a hard, flat surface.

• Set the parking brake.

• Shift the shift lever to “P”.

• Stop the engine.

• Turn on the emergency f ...

0.1246

.png)

.png)

.png)