Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT CHARCOAL CANISTER ASSEMBLY

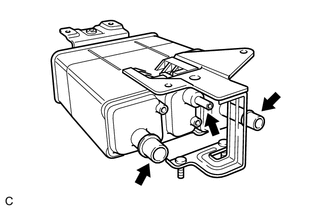

(a) Visually check the charcoal canister assembly.

|

(1) Visually check the charcoal canister assembly for cracks or damage. If cracks or damage are found, replace the charcoal canister assembly. |

|

(b) Check canister operation.

|

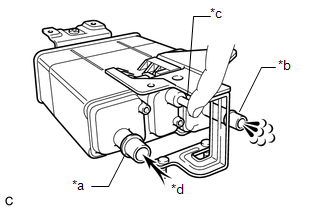

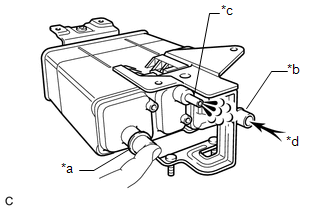

(1) With the purge line port closed, blow 0.5 kPa (0.005 kgf/cm2, 0.1 psi) of air into the vent line port, and check that air flows from the air line port. Text in Illustration

If the result is not as specified, replace the charcoal canister assembly. |

|

|

(2) With the vent line port closed, blow 0.5 kPa (0.005 kgf/cm2, 0.1 psi) of air into the air line port, and check that air flows from the purge line port. Text in Illustration

If the result is not as specified, replace the charcoal canister assembly. |

|

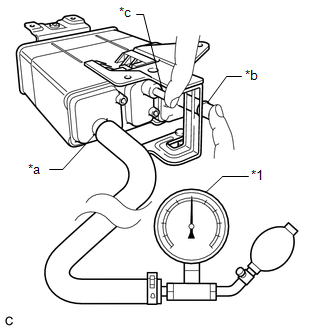

(c) Check for air leaks.

|

(1) Connect a pressure gauge to the vent line port of the charcoal canister assembly. Text in Illustration

|

|

(2) With the purge line port and the air line port closed, apply 20 kPa (150 mmHg, 5.91 in.Hg) of pressurized air into the vent line port, then confirm that pressure is retained for 1 minute.

If the result is not as specified, replace the charcoal canister assembly.

(d) Check the charcoal canister leak detection pump sub-assembly.

|

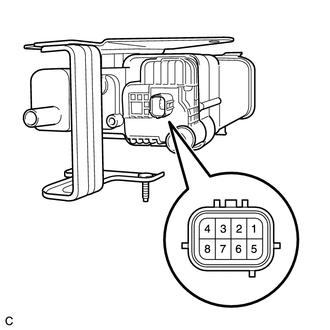

(1) Connect a positive (+) lead from the battery to terminal 5 and a negative (-) lead to terminal 1. |

|

(2) Check that a clicking sound is heard from the charcoal canister leak detection pump sub-assembly.

If the result is not as specified, replace the charcoal canister leak detection pump sub-assembly.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 FLOOR UNDER COVER

(a) Disengage the 4 nuts and clip, and remove the No. 1 floor under cover.

Text in Illustration

Nut (attached to under cov ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CHARCOAL CANISTER LEAK DETECTION PUMP SUB-ASSEMBLY

(a) Engage the 2 claws to install a new charcoal canister leak detection

pump sub-assembly to the ...

Other materials about Toyota Venza:

Inspection

INSPECTION

PROCEDURE

1. INSPECT ENGINE COOLANT TEMPERATURE SENSOR

Text in Illustration

*1

Component without harness connected

(Engine Coolant Temperature Sensor)

*2

Temperature °C (°F)

*3

...

Inspection

INSPECTION

PROCEDURE

1. INSPECT PARKING BRAKE SWITCH ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Switch Condition

...

Fuel Tank Cap

Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the fuel tank cap assembly and gasket are not

deformed or damaged.

Text in Illustration

*a

Gasket

...

0.129