Toyota Venza: Inspection

INSPECTION

PROCEDURE

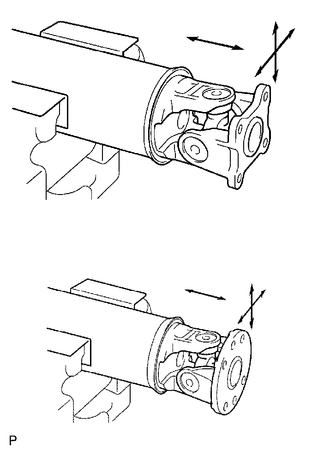

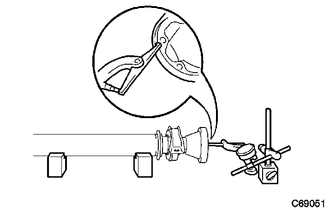

1. INSPECT UNIVERSAL JOINT SPIDER ASSEMBLY

|

(a) Check the spider bearing axial play by turning the flange while holding the shaft tightly. HINT: If necessary, replace the propeller with center bearing shaft assembly. |

|

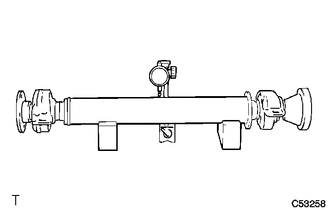

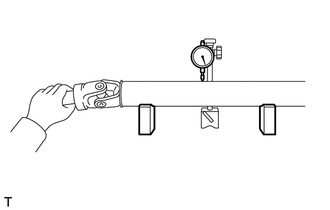

2. INSPECT INTERMEDIATE SHAFT

|

(a) Using a dial indicator, inspect the intermediate shaft sub-assembly. Maximum runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the intermediate shaft. If the shaft runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

|

(b) Using a dial indicator, inspect the front side universal joint flange runout in the vertical direction. Maximum runout: 0.1 mm (0.00394 in.) If the flange runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

|

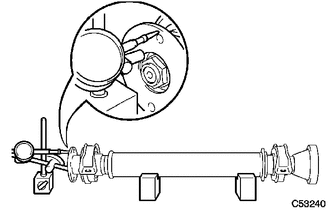

(c) Using a dial indicator, inspect the rear side universal joint flange runout in the vertical direction. Maximum runout: 0.1 mm (0.00394 in.) If the flange runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

|

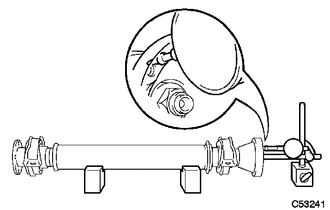

(d) Using a dial indicator, inspect the rear side universal joint flange runout in the horizontal direction. Maximum runout: 0.1 mm (0.00394 in.) If the flange runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

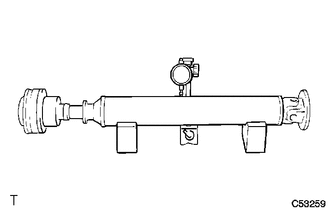

3. INSPECT PROPELLER SHAFT

|

(a) Using a dial indicator, inspect the propeller shaft. Maximum runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the propeller shaft. If the shaft runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

4. INSPECT REAR PROPELLER SHAFT

|

(a) Using a dial indicator, inspect the rear propeller shaft. Maximum runout: 0.4 mm (0.0157 in.) NOTICE: The dial indicator must be set at a right angle to the center of the rear propeller shaft. If the shaft runout is greater than the maximum, replace the propeller with center bearing shaft assembly. |

|

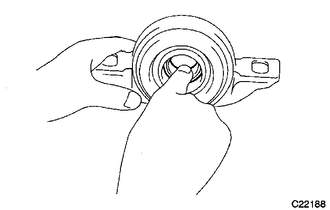

5. INSPECT NO. 1 CENTER SUPPORT BEARING ASSEMBLY

|

(a) Turn the No. 1 center support bearing assembly by hand while applying force in the rotation direction. Check that the bearing turns smoothly. |

|

(b) Check that the seals and bracket are not cracked or damaged.

If the No. 1 center support bearing assembly is damaged, worn, or does not turn freely, replace it.

6. INSPECT NO. 2 CENTER SUPPORT BEARING ASSEMBLY

(a) Turn the No. 2 center support bearing assembly by hand while applying force in the rotation direction. Check that the bearing turns smoothly.

(b) Check that the seals and bracket are not cracked or damaged.

If the No. 2 center support bearing assembly is damaged, worn, or does not turn freely, replace it.

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE PROPELLER SHAFT

(a) Place matchmarks on both flanges.

Text in Illustration

*1

Matchmark

...

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Remove SST from the transfer.

SST: 09325-20010

...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DOOR LOCK ASSEMBLY

NOTICE:

When reusing the removed front door lock assembly, replace the door

lock wiring harness seal on the connector with a new one.

Do not allow grease or dust to adhere to the do ...

Ignition Key Cylinder Light

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT TRANSPONDER KEY AMPLIFIER

(a) Connect a positive (+) lead from battery to terminal 2 and a negative

(-) lead to terminal 6.

...

Transmission Fluid Temperature Sensor "A" Circuit Low Input (P0712,P0713)

DESCRIPTION

The Automatic Transmission Fluid (ATF) temperature sensor converts the fluid

temperature into a resistance value for use by the TCM.

The TCM applies a voltage to the temperature sensor through terminal THO1 of

the TCM.

The sensor resistanc ...

0.149