Toyota Venza: Inspection

INSPECTION

PROCEDURE

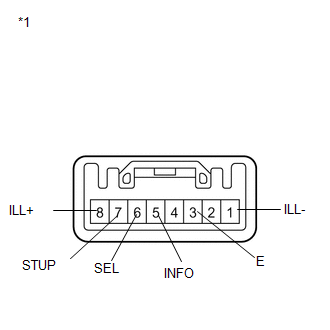

1. INSPECT DRIVE MONITOR SWITCH

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (E) - 5 (INFO) |

INFO CLOCK*1 or INFO*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 5 (INFO) |

INFO CLOCK*1 or INFO*2 switch is released |

10 kΩ or higher |

|

3 (E) - 6 (SEL) |

RESET H *1 or SELECT RESET*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 6 (SEL) |

RESET H *1 or SELECT RESET*2 switch is released |

10 kΩ or higher |

|

3 (E) - 7 (STUP) |

US/M M*1 or SETUP*2 switch is pressed |

Below 1 Ω |

|

3 (E) - 7 (STUP) |

US/M M*1 or SETUP*2 switch is released |

10 kΩ or higher |

- *1: w/o Rear View Monitor System

- *2: w/ Rear View Monitor System

(b) Apply battery voltage from the wire harness back side between the terminals of the switch, and check the lighting condition of the drive monitor switch.

OK:

|

Measurement Condition |

Condition |

Specified Condition |

|---|---|---|

|

Battery negative (-) → 1 (ILL-) Battery positive (+) → 8 (ILL+) |

Always |

Drive monitor switch illuminates |

|

*1 |

Component without harness connected (Drive Monitor Switch) |

HINT:

If the result is not as specified, replace the drive monitor switch (See page

.gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

...

Other materials about Toyota Venza:

Speed Signal Circuit

DESCRIPTION

The headlight leveling ECU assembly receives the vehicle speed signal from the

combination meter assembly.

HINT:

A voltage of 12 V or 5 V is output from each ECU and then input to the

combination meter. The signal is changed to a p ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT DRIVER SIDE SEAT BELT WARNING

(a) Turn the ignition switch to ON.

(b) When the driver side seat belt is not fastened, check that the driver side

seat belt warning light on the combination meter assembly blinks.

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

Use the following procedure to troubleshoot the engine immobiliser system.

*: Use the Techstream.

PROCEDURE

1.

VEHICLE BROUGHT TO WORKSHOP

NEXT

...

0.1134