Toyota Venza: Inspection

INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

Ensure that fingers or articles of clothing do not get caught in moving parts when performing this test.

PROCEDURE

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

|

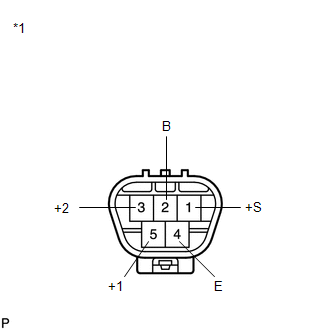

(a) Check the LO operation. (1) Connect a battery positive (+) lead to terminal 5 (+1) and a negative (-) lead to terminal 4 (E), and check that the motor operates at low speed (LO). OK: Motor operates at low speed (LO). Text in Illustration

|

|

(b) Check the HI operation.

(1) Connect a battery positive (+) lead to terminal 3 (+2) and a negative (-) lead to terminal 4 (E), and check that the motor operates at high speed (HI).

OK:

Motor operates at high speed (HI).

(c) Check the automatic stop (park) operation.

(1) Connect a battery positive (+) lead to terminal 5 (+1) and a negative (-) lead to terminal 4 (E). With the motor operating at low speed (LO), disconnect terminal 5 (+1) to stop the wiper motor operation at any position other than the matchmark.

(2) Using SST, connect terminals 1 (+S) and 5 (+1). Then connect a battery positive (+) lead to terminal 2 (B) and a negative (-) lead to terminal 4 (E) to restart the motor operation at low speed (LO).

SST: 09843-18040

|

(3) Check that the motor stops automatically at the automatic stop (park) position. OK: Motor stops automatically at the position. If the result is not as specified, replace the windshield wiper motor assembly. Text in Illustration

|

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

(a) for RH Side

(1) Operate the windshield wiper motor assembly.

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WIPER ARM HEAD CAP

(a) Using a screwdriver, remove the 2 front wiper arm head caps as shown

in the illustration.

Text in Illustration

...

Other materials about Toyota Venza:

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times.

Then remove the brake master cylinder from the brake booster.

PROCEDURE

1. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE DISC INSIDE DIAMETER

(a) Using a brake drum gauge or an equivalent tool, measure the inside

diameter of the disc.

Standard inside diameter of a new disc:

190 mm (7.48 in.)

Maximum inside diamete ...

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZE LIGHTING SYSTEM (EXT)

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Be sure to make a note of ...

0.1454