Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT PRELOAD

|

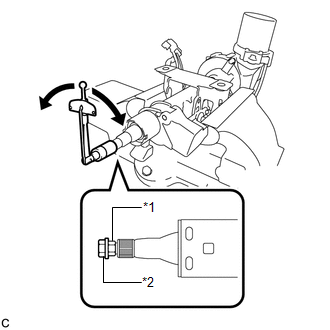

(a) Secure the steering column assembly in a vise. Text in Illustration

NOTICE: When using a vise, do not overtighten it. |

|

(b) Install a service nut to the steering main shaft.

Recommended service nut:

Thread diameter

12.0 mm (0.472 in.)

Thread pitch

1.25 mm (0.0492 in.)

(c) Install the steering wheel assembly set nut to the steering main shaft.

(d) Lock the steering wheel assembly set nut using the service nut.

(e) Using a torque wrench, turn the main shaft and measure the preload.

Torque:

Preload :

0.98-1.58 N·m {10-16 kgf·cm, 9-13 in·lbf}

If the preload is not as specified, replace the steering column assembly.

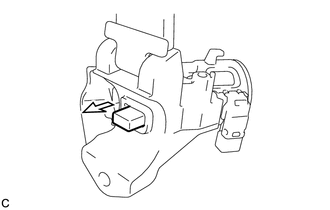

2. INSPECT STEERING LOCK OPERATION (w/o Smart Key System)

|

(a) Check that the steering lock mechanism is activated when the key is removed. |

|

|

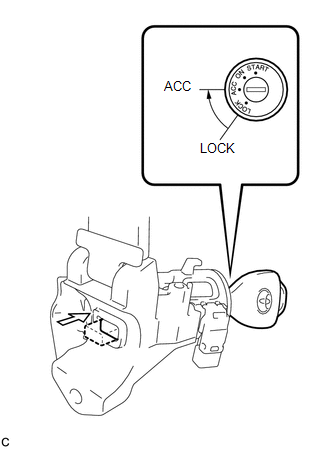

(b) Check that the steering lock mechanism is deactivated when the key is inserted and turned to the ACC position. HINT: If there is any abnormality, replace the ignition switch lock cylinder assembly or steering column upper bracket assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When using a vise, do not overtighten it.

PROCEDURE

1. REMOVE STEERING LOCK ACTUATOR ASSEMBLY (w/ Smart Key System)

(a) Secure the steering column ass ...

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

When using a vise, do not overtighten it.

PROCEDURE

1. INSTALL STEERING LOCK ACTUATOR ASSEMBLY (w/ Smart Key System)

(a) Secure the steering column ass ...

Other materials about Toyota Venza:

Basic Inspection

BASIC INSPECTION

When the malfunction is not confirmed by the DTC check, troubleshooting should

be carried out in all circuits considered to be possible causes of the problem.

In many cases, by carrying out the basic engine check shown in the following pr ...

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 FLOOR UNDER COVER

(a) Disengage the 4 nuts and clip, and remove the No. 1 floor under cover.

Text in Illustration

Nut (attached to under cover)

HINT:

Rotate the clip to disengage it. The 4 ...

Terminals Of Ecu

TERMINALS OF ECU

HINT:

Check from the rear of the connector while it is connected to the components.

1. NAVIGATION RECEIVER ASSEMBLY

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

...

0.1306