Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT INTAKE AIR CONTROL VALVE (for ACIS)

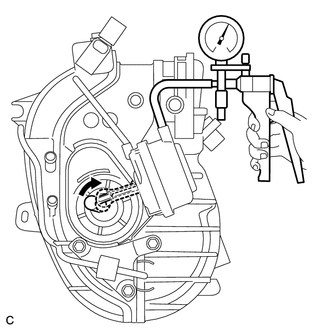

(a) Inspect the diaphragm.

|

(1) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg) or higher to the diaphragm chamber. Wait for 1 minute and check that the needle of the vacuum pump does not lower. If the result is not as specified, replace the intake manifold. |

|

(b) After applying vacuum in the step above, check that the actuator rod operates.

2. INSPECT VACUUM TANK AND CHECK VALVE

|

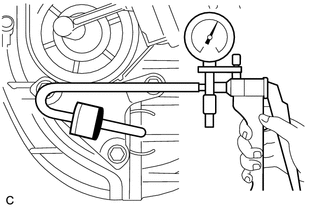

(a) Disconnect the vacuum hose from the check valve. |

|

(b) Using a vacuum pump, apply vacuum to the check valve. Wait for 1 minute and check that the needle of the vacuum pump does not lower.

If the result is not as specified, replace the check valve.

(c) Connect the vacuum hose to the check valve.

|

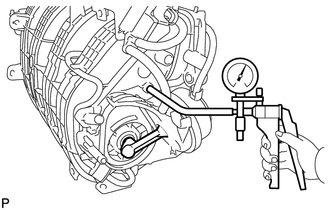

(d) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg) or higher to the vacuum tank. Wait for 1 minute and check that the needle of the vacuum pump does not lower. If the result is not as specified, replace the intake manifold. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

(See page ).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

When disconnecting the cable, some systems need to be initial ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE MOUNTING DAMPER

(a) Install the engine mounting damper with the 3 bolts.

Torque:

9.0 N·m {92 kgf·cm, 80 in·lbf}

...

Other materials about Toyota Venza:

ECM Power Source Circuit

DESCRIPTION

When the ignition switch is turned to ON, the battery voltage is applied to IGSW

of the ECM. The output signal from the MREL terminal of the ECM causes a current

to flow to the coil, closing the contact of the engine room junction block assemb ...

Operation Check

OPERATION CHECK

1. CHECK REMOTE CONTROL MIRROR FUNCTION

(a) Turn the ignition switch ON.

(b) With the mirror select switch set to L, check that the outer rear view mirror

LH surface moves up, down, left and right normally.

(c) With the mirror select swit ...

Chassis

General Maintenance

GENERAL MAINTENANCE

PROCEDURE

1. INSPECT STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering wheel free play (See page

).

(b) Check the steering linkage for looseness or damage.

(1) Check that the tie rod ends do not have any ...

0.1164