Toyota Venza: Heated Oxygen Sensor

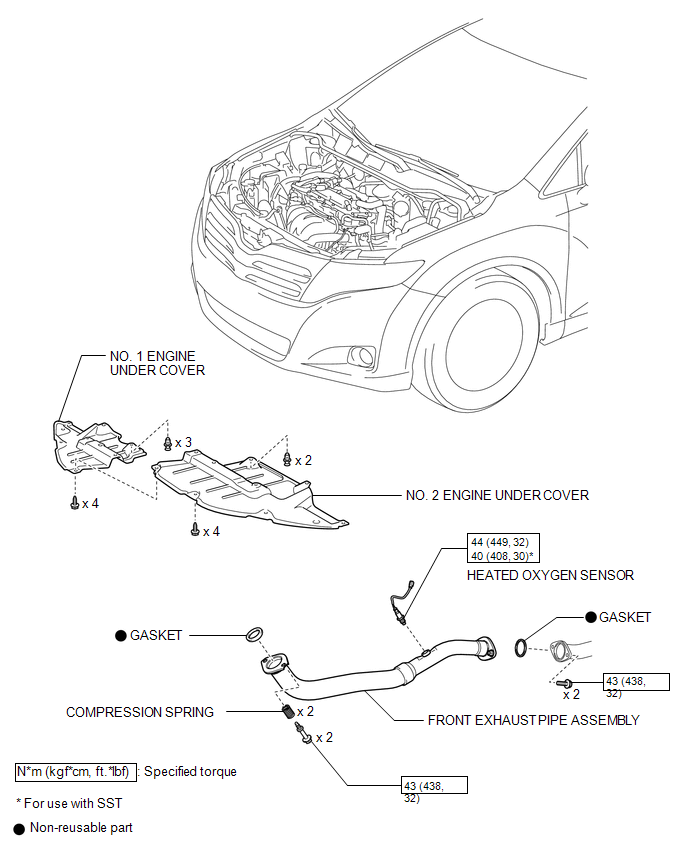

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. REMOVE FRONT EXHAUST PIPE ASSEMBLY

.gif)

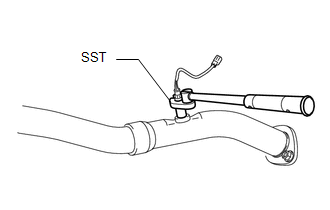

4. REMOVE HEATED OXYGEN SENSOR

|

(a) Using SST, remove the heated oxygen sensor from the front exhaust pipe assembly. SST: 09224-00011 |

|

Inspection

INSPECTION

PROCEDURE

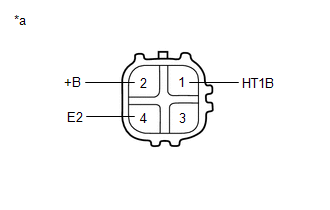

1. INSPECT HEATED OXYGEN SENSOR

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the result is not as specified, replace the heated oxygen sensor. |

|

Installation

INSTALLATION

PROCEDURE

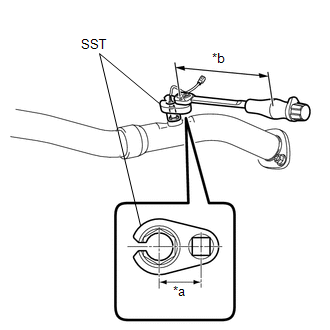

1. INSTALL HEATED OXYGEN SENSOR

HINT:

Perform "Inspection After Repair" after replacing the heated oxygen sensor (See

page .gif) ).

).

|

(a) Using SST, install the heated oxygen sensor to the front exhaust pipe assembly. Text in Illustration

SST: 09224-00011 Torque: without SST [Torque (N*m (kgf*cm, ft.*lbf))] : 44 N·m {449 kgf·cm, 32 ft·lbf} with SST [Reading of Torque wrench (N*m (kgf*cm, ft.*lbf))] : 40 N·m {408 kgf·cm, 30 ft·lbf} NOTICE: If the heated oxygen sensor has been struck or dropped, replace it. HINT:

|

|

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

.gif)

3. INSPECT FOR EXHAUST GAS LEAK

4. INSTALL NO. 2 ENGINE UNDER COVER

5. INSTALL NO. 1 ENGINE UNDER COVER

6. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the heated oxygen sensor

(See page .gif) ).

).

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

(a) Install a new gasket to the sensor.

Text in Illustration

*1

New Gasket

...

Ignition Coil And Spark Plug

Ignition Coil And Spark Plug

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2. REMOVE IGNITION COIL ASSEMBLY

(a) Disconnect the 4 ignition coil assembly con ...

Other materials about Toyota Venza:

Combination Meter ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Combination Meter ECU Communication Stop Mode

"Combination Meter" is not displayed on "CAN Bus Check" screen

of t ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Sound Signal Circuit between Radio Receiver and Stereo Jack Adapter

DESCRIPTION

The No. 1 stereo jack adapter assembly sends the sound signal from an

external device to the radio and display receiver assembly via this circuit.

The sound signal that has been sent is amplified by the radio and display

receiver ...

0.1378