Toyota Venza: Front Blower Motor

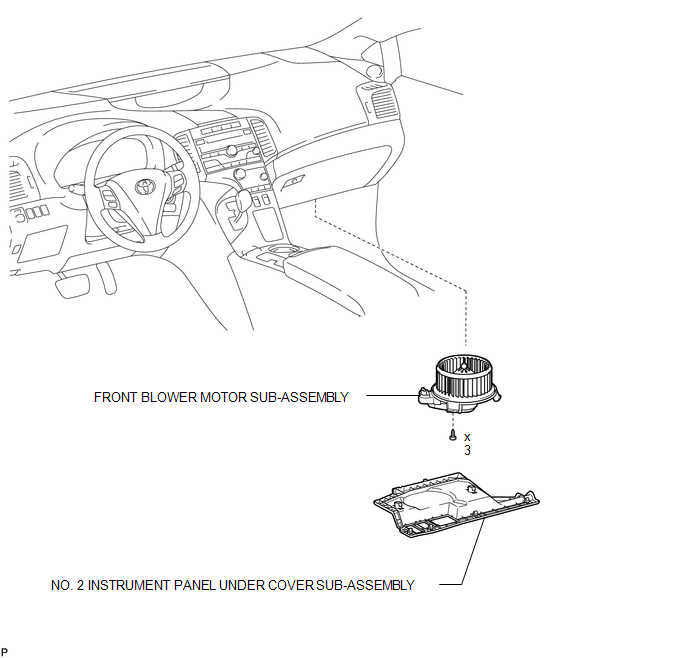

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

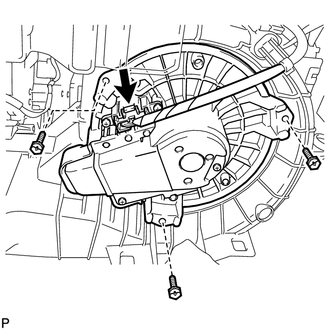

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Install the front blower motor sub-assembly with the 3 screws. |

|

(b) Connect the connector.

2. INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. REMOVE FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the 3 screws and front blower motor sub-assembly.

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL COOLER DRYER

(a) Using pliers, install a new cooler dryer to the modulator.

(b) Apply sufficien ...

Other materials about Toyota Venza:

Interior Light Auto Cut Circuit

DESCRIPTION

When battery saving control operates while the interior lights are on, the main

body ECU (driver side junction block assembly) opens the DOME CUT relay to turn

off the lights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fu ...

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HORN RELAY (ENGINE ROOM JUNCTION BLOCK ASSEMBLY)

(a) Remove the engine room junction block assembly from the engine room

relay block (See page ).

...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end frame.

2. INSTALL GENERATOR CL ...

0.1141

.png)