Toyota Venza: Adjustment

ADJUSTMENT

PROCEDURE

1. INSPECT AND ADJUST BRAKE PEDAL HEIGHT

(a) Check the brake pedal height.

(1) Turn back the carpet.

|

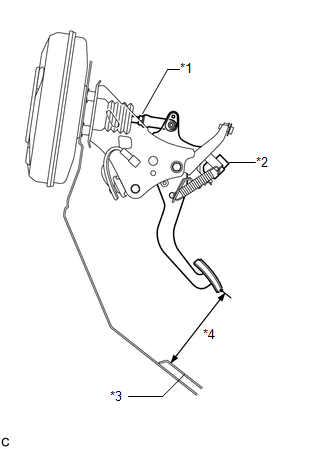

(2) Measure the brake pedal height from the dash panel to the bottom edge of the brake pedal pad. Text in Illustration

Standard pedal height: 135 to 145 mm (5.31 to 5.71 in.) If pedal height is incorrect, adjust the push rod length according to procedure below. |

|

(b) Adjust the push rod length.

(1) Remove the stop light switch assembly (See page

.gif) ).

).

(2) Remove the brake booster assembly (See page

.gif) ).

).

|

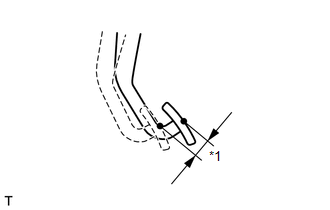

(3) Loosen the lock nut and adjust the push rod length*1 shown in the illustration by turning the brake master cylinder push rod clevis to achieve the length*1. Text in Illustration

Length*1: 155.1 to 156.1 mm (6.11 to 6.15 in.) |

|

(4) Tighten the lock nut.

Torque:

26 N·m {265 kgf·cm, 19 ft·lbf}

(5) Install the brake booster assembly (See page

.gif) ).

).

If the pedal height is incorrect even if the push rod length is adjusted, check that there is no damage to the brake pedal support assembly and dash panel.

- Even if there is damage, there is no problem if the reserve distance is within the standard value.

- If necessary, replace the brake pedal support assembly.

(6) Install the stop light switch assembly (See page

.gif) ).

).

(7) Check that the stop lights do not come on when the brake pedal is released.

(c) After adjusting the pedal height, check the brake pedal free play.

2. INSPECT BRAKE PEDAL FREE PLAY

(a) Stop the engine and firmly depress the brake pedal several times until no vacuum is left in the booster.

|

(b) Measure the free play of the brake pedal. Text in Illustration

Standard pedal free play: 1.0 to 3.0 mm (0.0394 to 0.118 in.) If the pedal free play is not as specified, check the stop light switch

clearance (See page |

|

3. INSPECT BRAKE PEDAL RESERVE DISTANCE

HINT:

Measure the distance at the same point used for the brake pedal height inspection.

(a) Start the engine.

(b) Depress the brake pedal and check the pedal reserve distance.

(1) Depress the brake pedal with a force of 500 N (51 kgf, 112.4 lbf).

(2) Measure the distance between the brake pedal and dash panel.

Standard pedal reserve distance:

28 mm (1.10 in.)

If the distance is not as specified, troubleshoot the brake system (See page

.gif) ).

).

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE BRAKE PEDAL RETURN SPRING

(a) Remove the brake pedal return spring from the brake pedal support

assembly.

...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL STOP LIGHT SWITCH CUSHION

(a) Install the stop light switch cushion to the brake pedal support assembly.

2. INSTALL BRAKE PEDAL PAD

(a) Install the brake pedal pad ...

Other materials about Toyota Venza:

Trailer towing tips

Your vehicle will handle differently when towing a trailer. Help to avoid an

accident, death or serious injury, keep the following in mind when towing:

• Speed limits for towing a trailer vary by state or province. Do not exceed

the posted towing speed ...

Microphone Circuit between Microphone and Radio Receiver

DESCRIPTION

The radio and display receiver assembly and inner rear view mirror assembly (amplifier

microphone assembly) are connected to each other using the microphone connection

detection signal lines.

Using this circuit, the radio and display receiver ...

If your vehicle overheats

The following may indicate that your vehicle is overheating.

• The engine coolant temperature gauge reaches the maximum, or a loss of

engine power is experienced. (For example, the vehicle speed does not increase.)

• Steam comes out from under the hood ...

0.1205

.png)