Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. SEPARATE FRONT DISC BRAKE CALIPER ASSEMBLY

.gif)

3. REMOVE FRONT DISC

.gif)

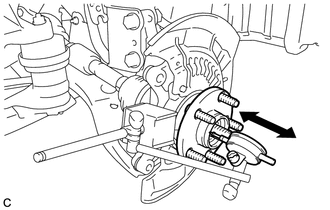

4. INSPECT FRONT AXLE HUB BEARING LOOSENESS

|

(a) Using a dial indicator, check for looseness near the center of the front axle hub. Maximum looseness: 0.05 mm (0.00196 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the looseness exceeds the maximum, replace the front axle hub bearing. |

|

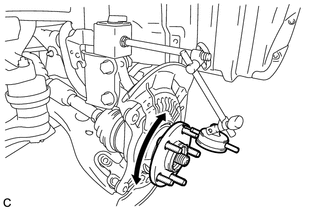

5. INSPECT FRONT AXLE HUB RUNOUT

|

(a) Using a dial indicator, check for runout on the surface of the axle hub outside the hub bolt. Maximum runout: 0.05 mm (0.00196 in.) NOTICE: Ensure that the dial indicator is set perpendicular to the measurement surface. If the runout exceeds the maximum, replace the front axle hub sub-assembly. |

|

6. INSTALL FRONT DISC

.gif)

7. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

.gif)

8. INSTALL FRONT WHEEL

Torque:

103 N┬Ęm {1050 kgf┬Ęcm, 76 ft┬Ęlbf}

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. REMO ...

Other materials about Toyota Venza:

Pressure Control Solenoid "C" Performance (Shift Solenoid Valve SL3) (P0796)

SYSTEM DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed

sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

Then the TCM compares the actual gear with the shift schedule in the TCM memo ...

Electrical Key Oscillator(for Rear Floor)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TONNEAU COVER ASSEMBLY (w/ Tonneau Cover)

2. REMOVE DECK BOARD ASSEMBLY

3. REMOVE NO. 3 DECK BOARD SUB-ASSEMBLY

4. REMOVE DECK SIDE TRIM BOX LH

5. REMOVE NO. 2 D ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL THROTTLE BODY ASSEMBLY

(a) Install a new gasket to the intake manifold.

(b) Install the fuel tube bracket with the bolt.

Torque:

7.5 N┬Ęm {76 kgf┬ ...

0.1265