Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

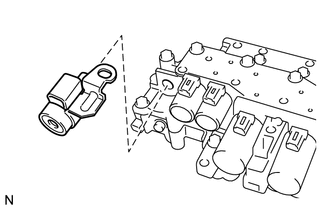

1. REMOVE TRANSMISSION WIRE

.gif)

2. REMOVE ATF TEMPERATURE SENSOR ASSEMBLY

|

(a) Remove the 4 bolts, ATF temperature sensor assembly and clamp from the valve body assembly. Text in Illustration

|

|

|

(b) Remove the O-ring from the ATF temperature sensor assembly. Text in Illustration

|

|

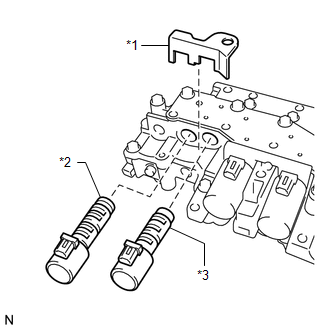

3. REMOVE SHIFT SOLENOID VALVE SL

|

(a) Remove the shift solenoid valve SL from the valve body assembly. |

|

4. REMOVE SHIFT SOLENOID VALVE SLT

|

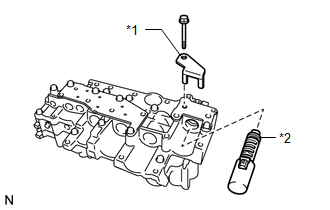

(a) Remove the lock plate and shift solenoid valve SLT from the valve body assembly. Text in Illustration

|

|

5. REMOVE SHIFT SOLENOID VALVE SLU

(a) Remove the shift solenoid valve SLU from the valve body assembly.

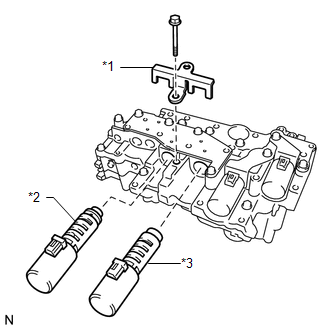

6. REMOVE SHIFT SOLENOID VALVE SL2

|

(a) Remove the bolt, lock plate and shift solenoid valve SL2 from the valve body assembly. Text in Illustration

|

|

7. REMOVE SHIFT SOLENOID VALVE SL1

(a) Remove the shift solenoid valve SL1 from the valve body assembly.

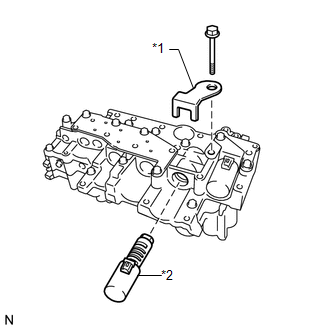

8. REMOVE SHIFT SOLENOID VALVE SL3

|

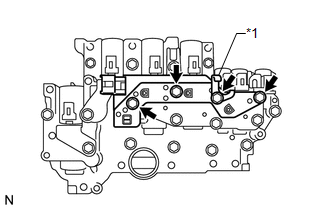

(a) Remove the bolt, lock plate and shift solenoid valve SL3 from the valve body assembly. Text in Illustration

|

|

9. REMOVE SHIFT SOLENOID VALVE SL4

|

(a) Remove the bolt, lock plate and shift solenoid valve SL4 from the valve body assembly. Text in Illustration

|

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Remove Engine Assembly with transaxle" through "Remove Automatic

Transaxle Assembly" (See p ...

Other materials about Toyota Venza:

Blind Spot Mirrors

The Blind Spot Mirrors increase the view of surrounding area to assist the driver

when checking surrounding area before changing lanes.

1. Blind Spot Mirror field of view

2. Main mirror field of view

- Mirror angle can be adjusted when

►V ...

Evaporative Emission Control System Leak Detected (Gross Leak) (P0455,P0456)

DTC SUMMARY

DTC No.

Monitoring Item

Malfunction Detection Condition

Trouble Area

Detection Timing

Detection Logic

P0455

EVAP gross leak

Leak detection pum ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.118

.png)