Toyota Venza: Back Door Lock

Components

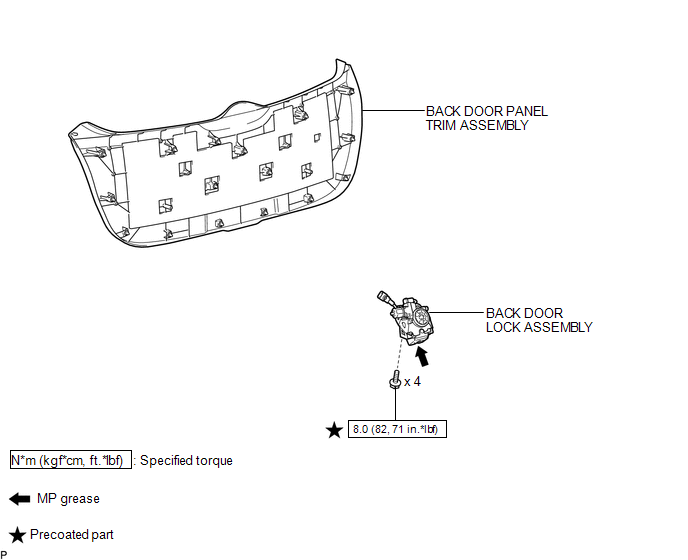

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

.gif)

2. REMOVE BACK DOOR LOCK ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Disengage the clamp.

(c) Remove the bolt.

|

(d) Remove the 3 bolts and back door lock assembly. |

|

Inspection

INSPECTION

PROCEDURE

1. INSPECT BACK DOOR LOCK ASSEMBLY

(a) Check the operation of the door lock motor.

.png)

(1) Apply the battery voltage to the door lock motor and check the operation of the door lock motor.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 1 (M+) Battery negative (-) → Terminal 2 (M-) |

Latch turns to full-latch position |

|

Battery positive (+) → Terminal 2 (M-) Battery negative (-) → Terminal 1 (M+) |

Latch turns to open-latch position |

If the result is not specified, replace the back door lock.

(b) Check the operation of the switch.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Latch Switch

|

Tester Connection |

Door Lock Latch Position |

Specified Condition |

|---|---|---|

|

5 (ULSW) - 4 (E) |

Open-latch |

Below 1 Ω |

|

5 (ULSW) - 4 (E) |

Half-latch |

10 kΩ or higher |

|

5 (ULSW) - 4 (E) |

Full-latch |

10 kΩ or higher |

|

5 (ULSW) - 4 (E) |

Over-latch |

Below 1 Ω |

Sector Switch

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

6 (DLSW) - 4 (E) |

Sector gear in neutral position (Sector switch on) |

Below 1 Ω |

|

6 (DLSW) - 4 (E) |

Sector gear not in neutral position (Sector switch off) |

10 kΩ or higher |

Back Door Courtesy Light Switch

|

Tester Connection |

Door Lock Latch Position |

Specified Condition |

|---|---|---|

|

3 (CTY) - 4 (E) |

Open-latch |

Below 1 Ω |

|

3 (CTY) - 4 (E) |

Half-latch |

Below 1 Ω |

|

3 (CTY) - 4 (E) |

Full-latch |

10 kΩ or higher |

|

3 (CTY) - 4 (E) |

Over-latch |

10 kΩ or higher |

If the result is not specified, replace the back door lock assembly.

Installation

INSTALLATION

PROCEDURE

1. INSTALL BACK DOOR LOCK ASSEMBLY

(a) Apply MP grease to the sliding parts of the back door lock assembly.

(b) Apply adhesive to the threads of the bolt.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

(c) Install the back door lock assembly with the 3 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

|

(d) Install the bolt. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

(e) Engage the clamp.

(f) Connect the connector.

2. INSTALL BACK DOOR PANEL TRIM ASSEMBLY

.gif)

Door Lock

Door Lock

...

Other materials about Toyota Venza:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BEARING BRACKET HOLE SNAP RING (for RH Side)

(a) Install a new bearing bracket hole snap ring to the front drive shaft assembly

RH.

2. INSTALL FRONT DRIVE SHAFT BEARING (for RH Side)

(a) Using SST, install a ne ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SEAT HEADREST ASSEMBLY

2. REMOVE FRONT SEAT REAR OUTER TRACK COVER

3. REMOVE FRONT SEAT REAR INNER TRACK COVER

4. REMOVE FRONT SEAT ASSEMBLY

5. REMOVE RECLINING POWER SEAT SWITCH KNOB

6. REMOVE SLIDE AND VER ...

Check CAN Bus Line for Short to +B

DESCRIPTION

There may be a short circuit between the CAN bus main wire and +B when no resistance

exists between terminals 6 (CANH) and 16 (BAT) or 14 (CANL) and 16 (BAT) of the

DLC3.

Symptom

Trouble Area

No resistan ...

0.1288

.png)

.png)

.png)

.png)