Toyota Venza: Transmission Wire(when Using The Engine Support Bridge)

Components

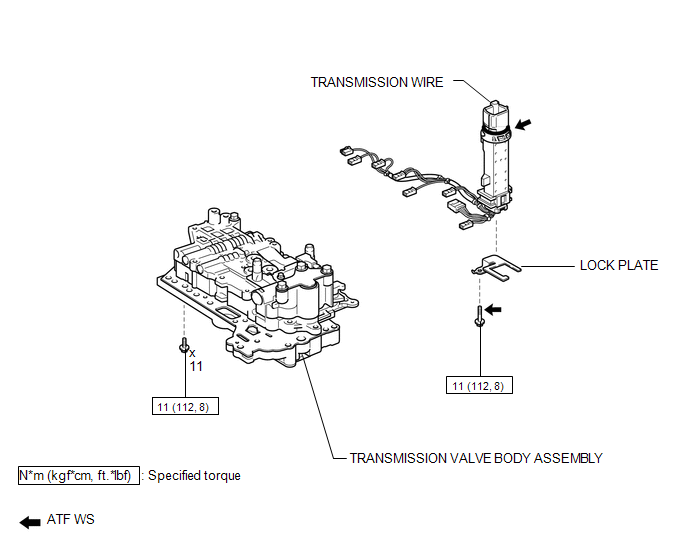

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION WIRE

|

(a) Coat the O-ring with ATF. |

|

(b) Coat the bolt with ATF.

(c) Install the transmission wire and lock plate to the transmission valve body assembly with the bolt.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

(d) Engage the clamp.

(e) Connect the 8 shift solenoid valve connectors.

(f) Connect the speed sensor connector.

2. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

See page .gif)

Removal

REMOVAL

PROCEDURE

1. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

See page .gif)

2. REMOVE TRANSMISSION WIRE

|

(a) Disconnect the speed sensor connector. |

|

(b) Disconnect the 8 shift solenoid valve connectors.

(c) Disengage the clamp.

|

(d) Remove the bolt, lock plate and transmission wire from the transmission valve body assembly. |

|

Transmission Wire(when Not Using The Engine Support Bridge)

Transmission Wire(when Not Using The Engine Support Bridge)

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

...

Other materials about Toyota Venza:

Inspection

INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the intake side and exhaust side.

PROCEDURE

1. INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

S ...

Inner Rear View Mirror Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the inner

rear view mirror assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the followin ...

Sound of Portable Player cannot be Heard from Speakers or Sound is Low

PROCEDURE

1.

CHECK PORTABLE PLAYER SETTINGS

(a) Check the portable player settings.

(1) Check that the volume is not set to "0".

(2) Check that mute is off.

(b) Check that the sound of the portable player can be h ...

0.1295

.png)

.png)

.png)