Toyota Venza: Terminals Of Ecu

TERMINALS OF ECU

1. TERMINALS OF ECU

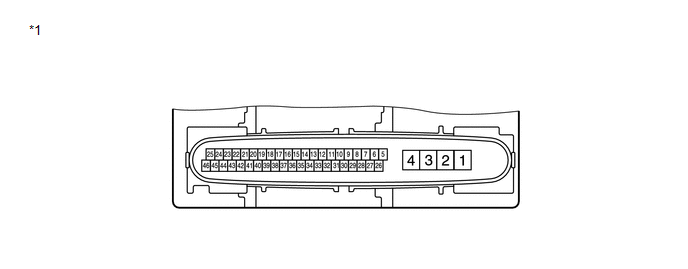

Text in Illustration

Text in Illustration

|

*1 |

Component without harness connected (Brake Actuator (Skid Control ECU)) |

|

Terminal No. (Symbol) |

Terminal Description |

|---|---|

|

1 (GND2) |

Pump motor ground |

|

2 (+BM) |

Motor relay power supply |

|

3 (+BS) |

Solenoid relay power supply |

|

4 (GND1) |

Skid control ECU ground |

|

5 (FL-) |

Front wheel speed LH (-) signal input |

|

6 (RL+) |

Rear wheel speed LH (+) signal input |

|

8 (RR+) |

Rear wheel speed RH (+) signal input |

|

9 (FR+) |

Front wheel speed RH (+) signal input |

|

10 (FR-) |

Front wheel speed RH (-) signal input |

|

11 (D/G) |

Diagnosis tester communication line |

|

13 (STP2) |

Stop light control relay input |

|

14 (CANL) |

CAN communication line L |

|

16 (TS) |

Sensor check input |

|

17 (CSW) |

VSC OFF switch input |

|

20 (FSW+) |

Brake pedal load sensing switch input |

|

26 (FL+) |

Front wheel speed LH (+) signal input |

|

27 (RL-) |

Rear wheel speed LH (-) signal input |

|

28 (IG1) |

ECU power supply |

|

29 (RR-) |

Rear wheel speed RH (-) signal input |

|

30 (STP) |

Stop light switch input |

|

33 (SP1) |

Speed signal output for speedometer |

|

35 (CANH) |

CAN communication line H |

|

39 (STP0) |

Stop light control relay output |

2. TERMINAL INSPECTION

(a) Disconnect the connector and measure the voltage and resistance on the wire harness side.

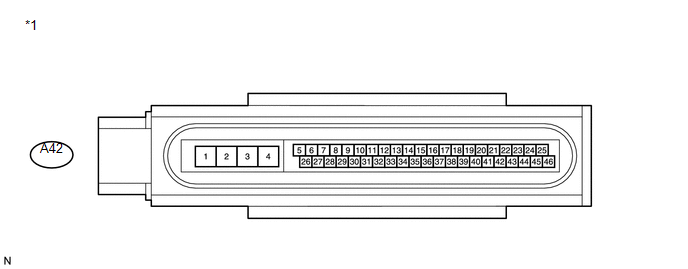

Text in Illustration

Text in Illustration

|

*1 |

Front view of wire harness connector (to Brake Actuator (Skid Control ECU)) |

HINT:

Voltage cannot be measured with the connector connected to the skid control ECU because the connector is watertight.

Standard|

Terminal No. (Symbol) |

Wiring Color |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|---|

|

A42-1 (GND2) - Body ground |

W-B - Body ground |

Pump motor ground |

Always |

Below 1 Ω |

|

A42-2 (+BM) - Body ground |

Y - Body ground |

Motor relay power supply |

Always |

11 to 14 V |

|

A42-3 (+BS) - Body ground |

GR - Body ground |

Solenoid relay power supply |

Always |

11 to 14 V |

|

A42-4 (GND1) - Body ground |

W - Body ground |

Skid control ECU ground |

Always |

Below 1 Ω |

|

A42-13 (STP2) - Body ground |

R - Body ground |

Stop light control relay input |

Stop light switch ON → OFF (Brake pedal depressed → released) |

8 to 14 V → Below 1.5 V |

|

A42-17 (CSW) - Body ground |

LG - Body ground |

VSC OFF switch input |

VSC OFF switch held ON → OFF (Not pressed) |

Below 1 Ω → 10 kΩ or higher |

|

A42-20 (FSW+) - Body ground |

R - Body ground |

Brake pedal load sensing switch input |

Brake pedal load sensing switch OFF → ON (Brake pedal depressed → released) |

950 to 1050 Ω → 203 to 223 Ω |

|

A42-28 (IG1) - Body ground |

GR - Body ground |

ECU power supply |

Ignition switch ON |

11 to 14 V |

|

A42-30 (STP) - Body ground |

P - Body ground |

Stop light switch input |

Stop light switch ON → OFF (Brake pedal depressed → released) |

8 to 14 V → Below 1.5 V |

|

A42-39 (STP0) - Body ground |

BR - Body ground |

Stop light control relay output |

Ignition switch ON |

11 to 14 V |

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

If there are no DTCs output and the problem still occurs, check the circuits

for each problem symptom in the order given in the following table and proceed to

the relevant ...

Diagnosis System

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting a vehicle with a diagnosis system, the only difference from

the usual troubleshooting procedure is connecting the Techstream to the vehicle

a ...

Other materials about Toyota Venza:

Key battery

Replace the battery with a new one if it is discharged.

- You will need the following items:

• Flathead screwdriver (To prevent damage to the key, cover the tip of the screwdriver

with rag.)

• Small Phillips-head screwdriver

• Lithium battery ...

ACC Monitor Malfunction (B2274)

DESCRIPTION

This DTC is stored when there is a problem in the ACC output circuit. The ACC

circuit is the circuit that goes from inside the power management control ECU to

the ACC relay.

DTC No.

DTC Detection Condition

Tro ...

Cruise SET Indicator Light Circuit

DESCRIPTION

The ECM detects a cruise control switch signal and sends it to the combination

meter assembly through CAN. Then the SET indicator light comes on.

The SET indicator light circuit uses CAN for communication. If there

is a malfunct ...

0.1339