Toyota Venza: Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

NOTICE:

- Move the shift lever to P and apply the parking brake before bleeding the brakes.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while bleeding the brakes.

- If brake fluid leaks onto any painted surface, immediately wash it off.

- If replacing is performed with the engine running or the engine switch on (IG), DTC C1441 will be stored. Make sure to clear the DTCs when work is complete.

HINT:

If any work is performed on the brake system or if air in the brake lines is suspected, bleed the brake system.

PROCEDURE

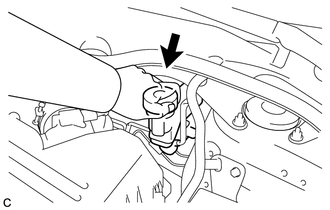

1. FILL RESERVOIR WITH BRAKE FLUID

|

(a) Remove the brake master cylinder reservoir filler cap. |

|

(b) Fill the reservoir with brake fluid.

Brake Fluid:

SAE J1703 or FMVSS No. 116 DOT 3

NOTICE:

- Make sure that there is sufficient brake fluid in the reservoir.

- Do not remove the filter from the brake master cylinder reservoir and be sure to fill with new brake fluid to avoid any potential contamination of the brake system. Contamination, for example by dirt particles or mineral oil, could lead to functional brake problem.

2. BLEED BRAKE LINE

NOTICE:

Bleed the brake line of the wheel farthest from the master cylinder first.

(a) Connect a vinyl tube to the bleeder plug.

(b) Depress the brake pedal several times, and while holding down the brake pedal, loosen the bleeder plug*1.

(c) When fluid stops coming out, tighten the bleeder plug and release the brake pedal*2.

(d) Repeat steps *1 and *2 until all the air in the brake fluid is completely bled out and the new brake fluid comes out.

(e) Tighten the bleeder plug completely.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

(f) Repeat the above steps to replace the brake fluid of the brake lines for each wheel.

3. INSPECT FOR BRAKE FLUID LEAK

4. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

5. CHECK AND CLEAR DTC

(See page .gif) )

)

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FLUID LEVEL

(a) Check the fluid level.

Text in Illustration

*1

MAX Line

*2

...

Bleeding

Bleeding

BLEEDING

CAUTION / NOTICE / HINT

NOTICE:

Do not allow brake fluid to adhere to any painted surface such as the

vehicle body. If brake fluid leaks onto any painted surface, immediately

...

Other materials about Toyota Venza:

Internal Control Module Accelerator Pedal Position Performance (P060D)

MONITOR DESCRIPTION

The ECM monitors the input signals of the accelerator pedal position sensor No.

1. When the input signals and control signals are deviated, the DTC is stored.

DTC No.

DTC Detection Condition

Trouble Area ...

Open or Short Circuit in ABS Solenoid Relay Circuit (C0278/11)

DESCRIPTION

The ABS solenoid relay supplies power to the ABS solenoid and TRAC solenoid.

The solenoid relay is turned on 1.5 seconds after the ignition switch is turned

to ON, and is turned off if an open or short in the solenoid is detected by self

diag ...

Transmission Control Switch Circuit

DESCRIPTION

When the shift lever is in S and it is moved toward "-" or "+", it is possible

to select different shift ranges (1st through 6th ranges).

Moving the shift lever toward "+" increases the shift range by one, and movi ...

0.1473