Toyota Venza: Rear Power Window RH Auto Up / Down Function does not Operate with Rear Power Window Switch RH

DESCRIPTION

If the manual up/down function can be performed but the auto up/down function cannot, the fail-safe mode may be functioning.

If the power window initialization (See page

.gif) ) has not been performed, the auto up/down function

) has not been performed, the auto up/down function

will not operate.

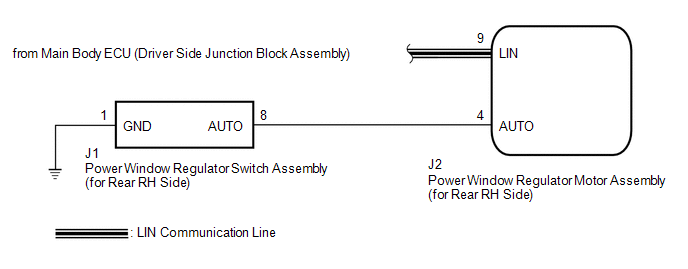

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The power window control system uses a multiplex communication system

(LIN communication system). Inspect the communication function by following

How to Proceed with Troubleshooting (See page

.gif) ). Troubleshoot the power window control

). Troubleshoot the power window control

system after confirming that the communication system is functioning properly. - When the power window regulator motor assembly (for rear RH side) is reinstalled or replaced, the power window control system must be initialized.

- After a door glass or a door glass run has been replaced, the jam protection

function may operate unexpectedly when the auto up function is used. In

such cases, the auto up function can be reinitialized by repeating the following

operations at least 5 times:

- Close the power window by fully pulling up the power window regulator switch assembly (for rear RH side) and holding it at the auto up position.

- Open the power window by fully pushing down the power window regulator switch assembly (for rear RH side).

- When the ECU determines that the power window regulator motor assembly (for rear RH side) has a malfunction, DTC B2311 is set.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (RR-Door Motor) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / RR-Door Motor / Data List.

(e) Read the Data List according to the display on the Techstream.

RR-Door Motor (Power Window Regulator Motor Assembly (for Rear RH Side))|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

RR Door P/W Auto SW |

Rear RH side power window auto switch signal / ON or OFF |

ON: Rear RH power window auto switch operated OFF: Rear RH power window auto switch not operated |

- |

OK:

On the Techstream screen, ON or OFF is displayed accordingly.

| NG | .gif) |

GO TO STEP 4 |

|

|

2. |

PERFORM INITIALIZATION (for Rear RH Side) |

(a) Initialize the power window regulator motor assembly (for rear RH side) (See

page .gif) ).

).

|

|

3. |

CHECK POWER WINDOW CONTROL SYSTEM (AUTO UP/DOWN FUNCTION) |

(a) Check that the rear RH side door power window moves when the auto up/down

function of the power window regulator switch assembly (for rear RH side) is operated

(See page .gif) ).

).

OK:

Rear RH side auto up/down function is normal.

| OK | .gif) |

END (PROBLEM DUE TO INITIALIZATION FAILURE) |

| NG | .gif) |

REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear RH Side) |

|

4. |

INSPECT POWER WINDOW REGULATOR SWITCH ASSEMBLY (for Rear RH Side) |

|

(a) Remove the power window regulator switch assembly (for rear RH side)

(See page |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

8 (AUTO) - 1 (GND) |

Auto up or auto down position |

Below 1 Ω |

|

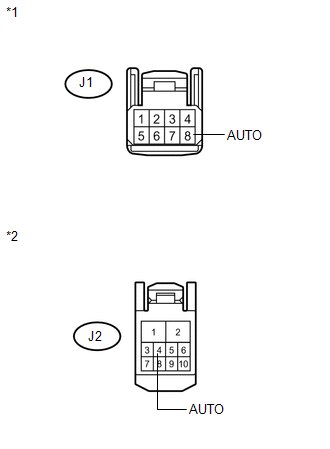

*1 |

Component without harness connected (Power Window Regulator Switch Assembly (for Rear RH Side)) |

| NG | .gif) |

REPLACE POWER WINDOW REGULATOR SWITCH ASSEMBLY (for Rear RH Side) |

|

|

5. |

CHECK HARNESS OR CONNECTOR (REAR RH SIDE SWITCH - REAR RH SIDE MOTOR) |

|

(a) Disconnect the power window regulator motor assembly (for rear RH side) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

J1-8 (AUTO) - J2-4 (AUTO) |

Always |

Below 1 Ω |

|

J1-8 (AUTO) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Power Window Regulator Switch Assembly (for Rear RH Side)) |

|

*2 |

Front view of wire harness connector (to Power Window Regulator Motor Assembly (for Rear RH Side)) |

| OK | .gif) |

REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (for Rear RH Side) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Rear Power Window LH Auto Up / Down Function does not Operate with Rear Power

Window Switch LH

Rear Power Window LH Auto Up / Down Function does not Operate with Rear Power

Window Switch LH

DESCRIPTION

If the manual up/down function can be performed but the auto up/down function

cannot, the fail-safe mode may be functioning.

If the power window initialization (See page

) has not be ...

Key-off Operation Function Operates even if Operating Conditions are not Satisfied

Key-off Operation Function Operates even if Operating Conditions are not Satisfied

DESCRIPTION

When the front doors are closed, each power window regulator motor assembly

can control its power window operation for approximately 45 seconds after

the ignition switch is ...

Other materials about Toyota Venza:

ECU Power Source Circuit

DESCRIPTION

This is the power source for the tire pressure warning ECU.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the tire pressure warning ECU, read the transmitter IDs

stored in the old ECU using the Techstream and writ ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Check CAN Bus Lines for Short Circuit

DESCRIPTION

There may be a short circuit in the CAN bus main wire and/or CAN branch wire

when the resistance between terminals 6 (CANH) and 14 (CANL) of the DLC3 is below

54 Ω.

Symptom

Trouble Area

Resistance betwe ...

0.1392

.gif)

.png)