Toyota Venza: Power Source Circuit

DESCRIPTION

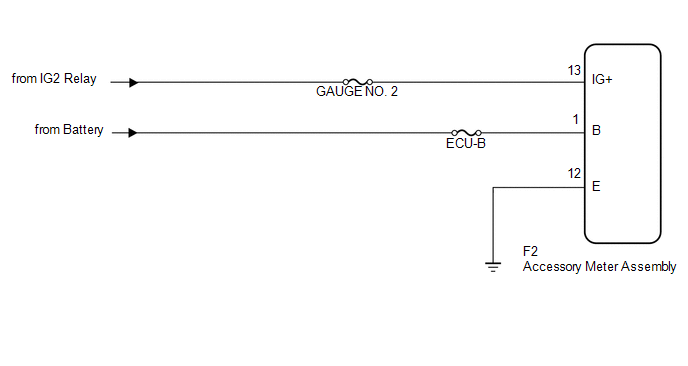

1. w/o Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly. This circuit provides two types of power sources; one is a constant power source mainly used as a backup power source, and the other is a power source mainly used for signal transmission.

HINT:

If the accessory meter assembly displays "1:00" when the ignition switch is turned off, then to ON again, the B terminal has a malfunction.

The maximum clock assembly margin of error is -4 to 4 seconds per day when the temperature is between -20°C (-4°F) and 60°C (140°F).

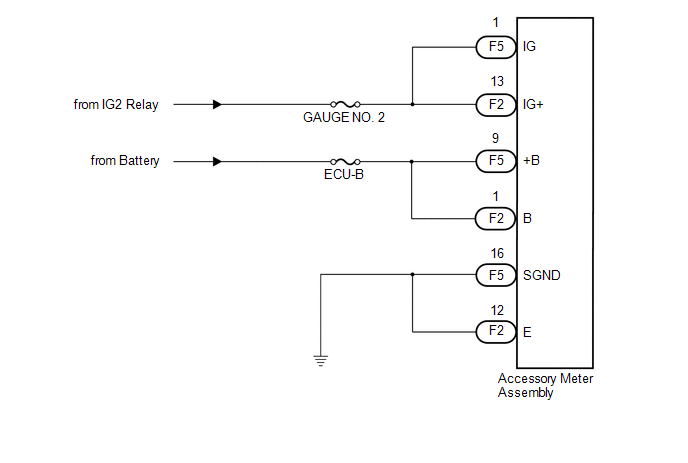

2. w/ Multi-information Display

(a) This circuit is the power source circuit for the accessory meter assembly. This circuit provides two types of power sources; one is a constant power source mainly used as a backup power source, and the other is a power source mainly used for signal transmission.

HINT:

If the accessory meter assembly displays "1:00" when the ignition switch is turned off, then to ON again, the +B terminal has a malfunction.

The maximum clock assembly margin of error is -4 to 4 seconds per day when the temperature is between -20°C (-4°F) and 60°C (140°F).

WIRING DIAGRAM

1. w/o Multi-information Display

2. w/ Multi-information Display

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR |

(a) w/o Multi-information Display

|

(1) Disconnect the F2 connector. |

|

(2) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-1 (B) - Body ground |

Always |

11 to 14 V |

|

F2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

(3) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-12 (E) - Body ground |

Always |

Below 1 Ω |

|

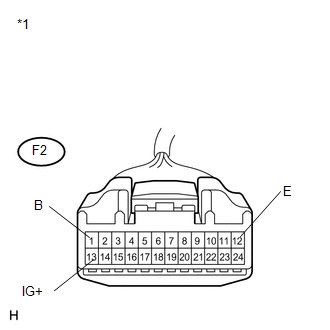

*1 |

Front view of wire harness connector (to Accessory Meter Assembly) |

(b) w/ Multi-information Display

|

(1) Disconnect the F2 and F5 connectors. |

|

(2) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F5-1 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

F5-9 (+B) - Body ground |

Always |

11 to 14 V |

|

F2-1 (B) - Body ground |

Always |

11 to 14 V |

|

F2-13 (IG+) - Body ground |

Ignition switch ON |

11 to 14 V |

(3) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-12 (E) - Body ground |

Always |

Below 1 Ω |

|

F5-16 (SGND) - Body ground |

Always |

Below 1 Ω |

|

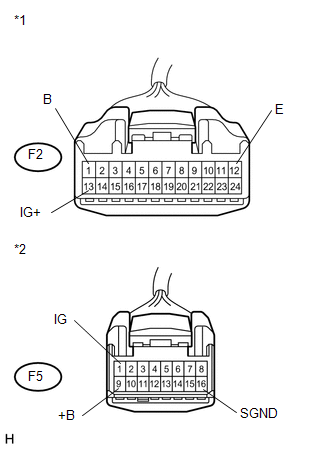

*1 |

Front view of wire harness connector (to Accessory Meter Assembly) |

|

*2 |

Front view of wire harness connector (to Accessory Meter Assembly ) |

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Speed Signal Circuit

Speed Signal Circuit

DESCRIPTION

The combination meter assembly receives the vehicle speed signal from this circuit.

The wheel speed sensors produce an output that varies according to the vehicle speed.

The wheel spe ...

Mirror (int)

Mirror (int)

...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

(See page )

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery terminal. Therefore, make sure to read the

disconnecting the cable fr ...

Portable Player cannot be Connected Manually/Automatically

CAUTION / NOTICE / HINT

HINT:

Some versions of "Bluetooth" compatible audio players may not function properly,

or the functions may be limited using the radio and display receiver assembly, even

if the portable audio player itself can play file ...

Transmission Fluid Pressure Sensor / Switch "E" Circuit Low (P0989,P0990)

DESCRIPTION

ATF pressure switch No. 3 is installed in the lock-up solenoid ATF output passage

and is used to detect a malfunction in the lock-up solenoid.

DTC No.

DTC Detection Condition

Trouble Area

P0989

...

0.1269