Toyota Venza: Open in Occupant Classification ECU Battery Positive Line (B1794)

DESCRIPTION

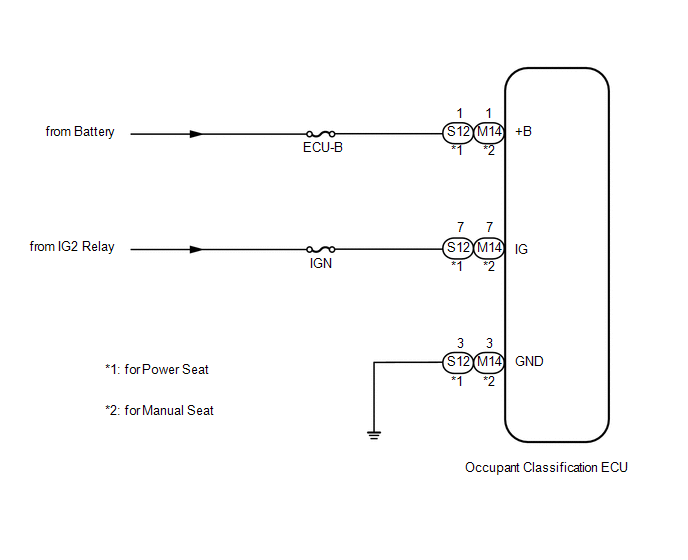

This circuit consists of the occupant classification ECU and power source circuit (battery, fuse and wire harness).

DTC B1794 is recorded when a malfunction is detected in the occupant classification ECU or power source circuit.

HINT:

If DTC B1794 is output after turning the ignition switch from off to ON and to off 50 times in a row when a malfunction occurs in the power circuit for the occupant classification system.

This DTC is output if a malfunction is detected even after being cleared unless the normal system code is input.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1794 |

|

|

When DTC B1650/32 is detected as a result of troubleshooting for the airbag system, check the DTCs stored in the occupant classification ECU. When DTC B1794 is output, perform troubleshooting for the DTC.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK BATTERY |

(a) Measure the voltage of the battery.

Standard Voltage:

11 to 14 V

| NG | .gif) |

REPLACE BATTERY |

|

|

2. |

CHECK WIRE HARNESS (SOURCE VOLTAGE) |

|

(a) Turn the ignition switch off. |

|

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Disconnect the connector from the occupant classification ECU.

(d) Connect the cable to the negative (-) battery terminal.

(e) Turn the ignition switch to ON.

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

for Power Seat

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

S12-1 (+B) - Body ground |

Always |

11 to 14 V |

|

S12-7 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

for Manual Seat

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M14-1 (+B) - Body ground |

Always |

11 to 14 V |

|

M14-7 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

(g) Turn the ignition switch off.

(h) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for Power Seat

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

S12-3 (GND) - Body ground |

Always |

Below 1 Ω |

for Manual Seat

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M14-3 (GND) - Body ground |

Always |

Below 1 Ω |

|

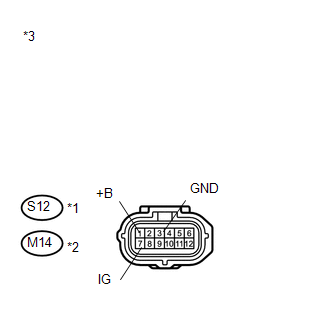

*1 |

for Power Seat |

|

*2 |

for Manual Seat |

|

*3 |

Front view of wire harness connector (to Occupant Classification ECU) |

| NG | .gif) |

REPLACE WIRE HARNESS |

|

|

3. |

CHECK DTC |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Connect the connector to the occupant classification ECU.

(d) Connect the Techstream to the DLC3.

(e) Connect the cable to the negative (-) battery terminal.

(f) Turn the ignition switch to ON.

(g) Clear the DTCs stored in the occupant classification ECU (See page

.gif) ).

).

(h) Clear the DTCs stored in the center airbag sensor assembly (See page

.gif) ).

).

(i) Turn the ignition switch off.

(j) Turn the ignition switch to ON, and wait for at least 10 seconds.

(k) Using the Techstream, check for DTCs of the occupant classification ECU (See

page .gif) ).

).

OK:

DTC B1794 is not output.

HINT:

Codes other than DTC B1794 may be output at this time, but they are not related to this check.

| OK | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

4. |

REPLACE OCCUPANT CLASSIFICATION ECU |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Replace the occupant classification ECU (See page

.gif) ).

).

|

|

5. |

PERFORM ZERO POINT CALIBRATION |

(a) Connect the cable to the negative (-) battery terminal.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Using the Techstream, perform Zero Point Calibration (See page

.gif) ).

).

OK:

"Zero Point Calibration is complete." is displayed.

|

|

6. |

PERFORM SENSITIVITY CHECK |

(a) Using the Techstream, perform Sensitivity Check (See page

.gif) ).

).

Standard:

27 to 33 kg (59.5 to 72.8 lb)

| NEXT | .gif) |

END |

Occupant Classification Sensor Power Supply Circuit Malfunction (B1793)

Occupant Classification Sensor Power Supply Circuit Malfunction (B1793)

DESCRIPTION

The occupant classification sensor power supply circuit consists of the occupant

classification ECU and occupant classification sensors.

DTC B1793 is recorded when a malfunction is det ...

Center Airbag Sensor Assembly Communication Circuit Malfunction (B1790)

Center Airbag Sensor Assembly Communication Circuit Malfunction (B1790)

DESCRIPTION

The center airbag sensor assembly communication circuit consists of the occupant

classification ECU and center airbag sensor assembly.

DTC B1790 is recorded when a malfunction is detec ...

Other materials about Toyota Venza:

Rear Airbag Sensor LH Circuit Malfunction (B1635/24)

DESCRIPTION

The side collision sensor LH circuit (to determine deployment of the front seat

side airbag assembly LH and curtain shield airbag assembly LH) is composed of the

center airbag sensor assembly, rear airbag sensor LH and side airbag sensor LH.

...

Throttle / Pedal Position Sensor / Switch "D" Circuit (P2120,P2122,P2123,P2125,P2127,P2128,P2138)

DESCRIPTION

HINT:

This Electronic Throttle Control System (ETCS) does not use a throttle

cable.

These DTCs relate to the accelerator pedal sensor assembly.

The accelerator pedal sensor assembly is mounted on the accelerator pedal brack ...

Starter Relay Circuit High (P0617)

DESCRIPTION

While the engine is being cranked, battery voltage is applied to terminal STA

of the TCM.

If the TCM detects the Starter Control (STA) signal while the vehicle is being

driven, it determines that there is a malfunction in the STA circuit. The ...

0.1514

.gif)