Toyota Venza: MIL Circuit

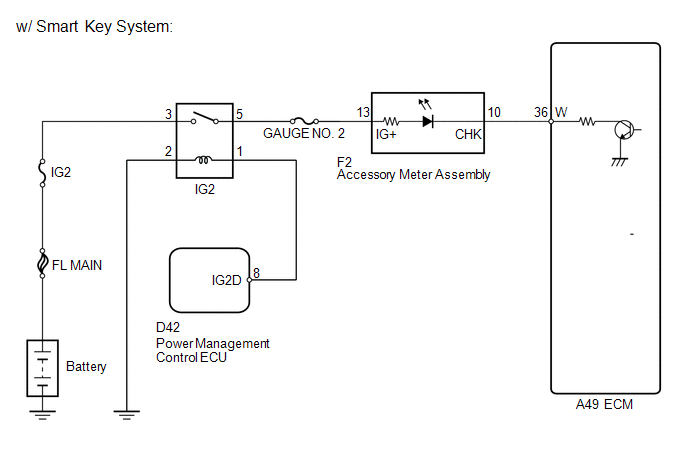

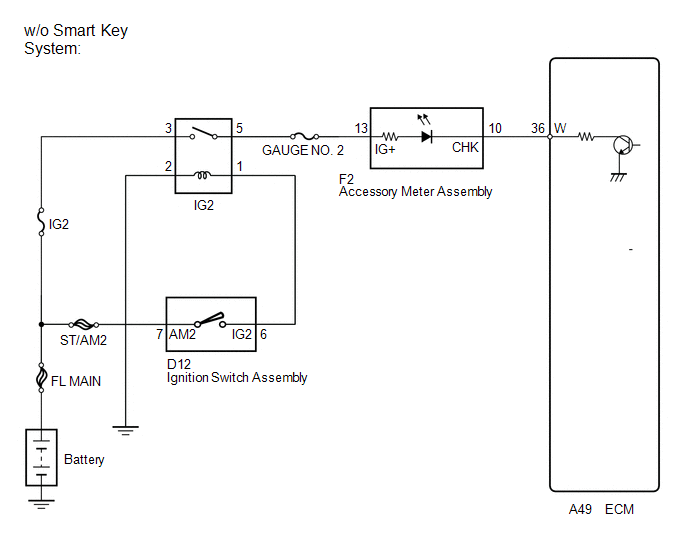

DESCRIPTION

The MIL (Malfunction Indicator Lamp) is used to indicate vehicle malfunctions detected by the ECM. By turning the ignition switch to ON, power is supplied to the MIL circuit, and the ECM provides the circuit ground which illuminates the MIL.

The MIL operation can be checked visually. When the ignition switch is turned to ON, the MIL should be illuminated and should then turn off. If the MIL remains illuminated or is not illuminated, conduct the following troubleshooting procedure. If the ECM detects any trouble, the MIL illuminates. At this time, the ECM records a DTC in the memory.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK THAT MIL ILLUMINATES |

(a) Turn the ignition switch to ON.

(b) Check the illumination of the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL remains illuminated (Illuminated at all) |

A |

|

MIL remains off (Does not illuminate at all) |

B |

|

MIL illuminates, but turns off after engine is started |

C |

| B | .gif) |

GO TO STEP 5 |

| C | .gif) |

CHECK FOR INTERMITTENT PROBLEMS |

|

|

2. |

CHECK WHETHER MIL TURNS OFF |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Check if any DTCs have been stored. Note any DTCs.

(f) Clear the DTCs (See page .gif) ).

).

(g) Check if the MIL goes off.

|

Result |

Proceed to |

|---|---|

|

MIL goes off |

A |

|

MIL does not go off |

B |

| A | .gif) |

REPAIR CIRCUIT INDICATED BY OUTPUT DTC |

|

|

3. |

CHECK HARNESS AND CONNECTOR (CHECK FOR SHORT IN WIRE HARNESS) |

|

(a) Disconnect the ECM connector. |

|

(b) Turn the ignition switch to ON.

(c) Check if the MIL is illuminated.

|

Result |

Proceed to |

|---|---|

|

MIL is not illuminated |

A |

|

MIL is illuminated |

B |

|

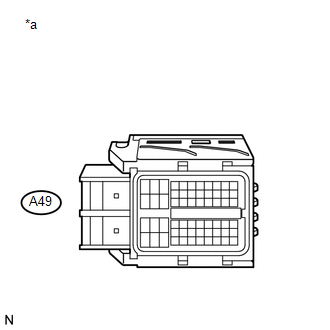

*a |

Front view of wire harness connector (to ECM) |

| A | .gif) |

REPLACE ECM |

|

|

4. |

CHECK HARNESS AND CONNECTOR (ACCESSORY METER ASSEMBLY - ECM) |

(a) Disconnect the accessory meter assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-10 (CHK) or A49-36 (W) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (ACCESSORY METER ASSEMBLY - ECM) |

|

5. |

CHECK IF ENGINE STARTS |

(a) Start the engine.

|

Result |

Proceed to |

|---|---|

|

Engine starts |

A |

|

Engine does not start* |

B |

HINT:

*: The Techstream cannot communicate with the ECM.

| B | .gif) |

GO TO VC OUTPUT CIRCUIT |

|

|

6. |

CHECK HARNESS AND CONNECTOR (ECM TERMINAL VOLTAGE) |

(a) Disconnect the ECM connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A49-36 (W) - Body ground |

Ignition switch ON |

11 to 14 V |

| OK | .gif) |

REPLACE ECM |

|

|

7. |

CHECK HARNESS AND CONNECTOR (ACCESSORY METER ASSEMBLY - ECM) |

(a) Disconnect the accessory meter assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F2-10 (CHK) - A49-36 (W) |

Always |

Below 1 Ω |

| OK | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (ACCESSORY METER ASSEMBLY - ECM) |

Brake Override System

Brake Override System

DESCRIPTION

When the vehicle is being driven, depressing the accelerator pedal sensor assembly

and brake pedal will activate the brake override system to restrict driving torque.

The conditions f ...

Throttle Body

Throttle Body

...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FOR COOLANT LEAK

HINT:

The sliding surface inside the engine water pump assembly is lubricated

by engine coolant. As some engine coolant is discharged during normal operation,

engine coolant residu ...

Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2) (P0778)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid valves, the TCM controls the remaining normal shift solenoid

...

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE SWITCH

(a) Attach the 2 claws to install the engine switch.

2. INSTALL LOWER INSTRUMENT PANEL FINISH PANEL ASSEMBLY

(a) Connect the connector.

...

0.1451

.gif)