Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL CHECK VALVE GROMMET

(a) Install a new check valve grommet to the brake booster assembly.

2. INSTALL BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Install the brake vacuum check valve assembly to the brake booster assembly.

3. INSTALL BRAKE MASTER CYLINDER PUSH ROD CLEVIS

(a) Temporarily install the lock nut and brake master cylinder push rod clevis to the brake booster assembly.

|

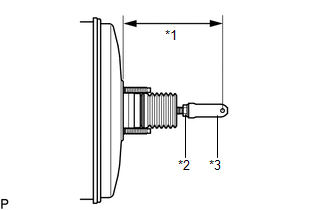

(b) Set the push rod length as shown in the illustration. Text in Illustration

Standard length*1: 155.1 to 156.1 mm (6.11 to 6.15 in.) |

|

(c) Tighten the lock nut.

Torque:

26 N·m {265 kgf·cm, 19 ft·lbf}

4. INSTALL BRAKE BOOSTER GASKET

|

(a) Install a new brake booster gasket to the brake booster assembly. |

|

5. INSTALL BRAKE BOOSTER ASSEMBLY

|

(a) Install the brake booster assembly to the body with the 4 nuts. Torque: 13 N·m {130 kgf·cm, 9 ft·lbf} NOTICE: Do not damage the brake lines. |

|

6. INSTALL PUSH ROD PIN

|

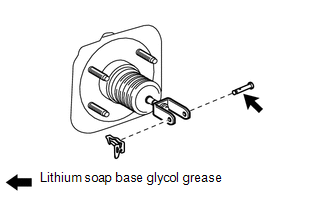

(a) Apply lithium soap base glycol grease to the push rod pin. |

|

(b) Connect the brake master cylinder push rod clevis to the brake pedal sub-assembly, and install the push rod pin and a new clip as shown in the illustration.

7. INSTALL NO. 1 VACUUM HOSE CONNECTOR (for 1AR-FE)

|

(a) Install the No. 1 vacuum hose connector with the 2 nuts. Torque: 5.4 N·m {55 kgf·cm, 48 in·lbf} |

|

(b) Connect the vacuum hose to the brake booster assembly, and slide the clip to secure the vacuum hose.

8. CONNECT VACUUM HOSE (for 2GR-FE)

|

(a) Connect the vacuum hose to the brake booster assembly, and slide the clip to secure the vacuum hose. |

|

9. INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

.gif)

10. FILL RESERVOIR WITH BRAKE FLUID

.gif)

11. BLEED BRAKE MASTER CYLINDER

.gif)

12. BLEED BRAKE LINE

.gif)

13. INSPECT FOR BRAKE FLUID LEAK

14. INSPECT FLUID LEVEL IN RESERVOIR

.gif)

15. INSPECT AND ADJUST BRAKE PEDAL

HINT:

See page .gif)

16. INSTALL SECURITY HORN ASSEMBLY (w/ Security Horn)

.gif)

17. INSTALL AIR CLEANER CASE (for 1AR-FE)

.gif)

18. INSTALL AIR CLEANER CASE (for 2GR-FE)

.gif)

19. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

20. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1AR-FE)

.gif)

21. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 2GR-FE)

.gif)

22. INSTALL OUTER COWL TOP PANEL

.gif)

23. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

.gif)

24. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

.gif)

25. INSTALL FRONT FENDER TO COWL SIDE SEAL RH

.gif)

26. INSTALL FRONT FENDER TO COWL SIDE SEAL LH

.gif)

27. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY RH

.gif)

28. INSTALL FRONT WIPER ARM AND BLADE ASSEMBLY LH

.gif)

29. INSTALL FRONT WIPER ARM HEAD CAP

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Check that there is ventilation from the booster to the engine, and

no ventilation from the engine to the booste ...

Brake Fluid

Brake Fluid

...

Other materials about Toyota Venza:

Illumination Circuit

DESCRIPTION

Power is supplied to the radio and display receiver assembly and steering pad

switch assembly illumination when the light control switch is in the tail or head

position.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

The vehicle ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is displayed during the DTC check, inspect the trouble areas

listed for that code. For details of the code, refer to the "See page" below.

Power Steering System

DTC Code

...

Automatic anti-glare function

Responding to the level of brightness of the headlights of vehicles behind, the

reflected light is automatically reduced.

Changing automatic anti-glare function mode ON/OFF

When the automatic anti-glare function is in ON mode, the indicator illuminates.

...

0.115

.png)

.png)

.png)

.png)