Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR

|

(a) Install the No. 1 manifold converter insulator to the exhaust manifold converter sub-assembly with the 4 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

2. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Install the No. 2 exhaust manifold heat insulator to the exhaust manifold converter sub-assembly with the 2 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

3. INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

|

(a) Install a new gasket onto the cylinder head sub-assembly. |

|

|

(b) Temporarily install the exhaust manifold converter sub-assembly to the cylinder head sub-assembly with the 5 nuts. |

|

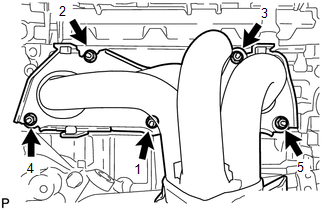

(c) Tighten the 5 nuts in the order shown in the illustration.

Torque:

35 N·m {357 kgf·cm, 26 ft·lbf}

4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

|

(a) Install the No. 1 exhaust manifold heat insulator to the exhaust manifold converter sub-assembly with the 4 bolts. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

5. INSTALL NO. 2 MANIFOLD STAY

|

(a) Install the No. 2 manifold stay to the exhaust manifold converter sub-assembly and stiffening crankcase assembly with the bolt and nut. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

6. INSTALL MANIFOLD STAY

|

(a) Install the manifold stay to the exhaust manifold converter sub-assembly and stiffening crankcase assembly with the bolt and nut. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

7. INSTALL AIR FUEL RATIO SENSOR

.gif)

8. INSTALL FRONT EXHAUST PIPE ASSEMBLY

|

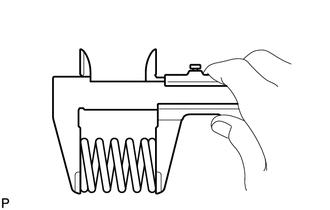

(a) Using a vernier caliper, measure the free length of the compression spring. Minimum Free Length: 41.5 mm (1.63 in.) If the length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the exhaust manifold converter sub-assembly.

|

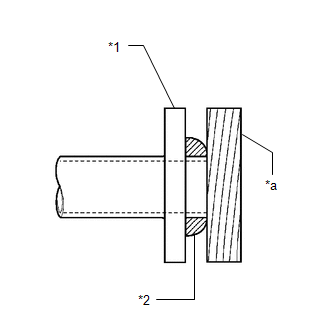

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the exhaust manifold converter sub-assembly. Text in Illustration

NOTICE:

|

|

(d) Install a new gasket to the center exhaust pipe assembly.

|

(e) Install the front exhaust pipe assembly to the exhaust manifold converter sub-assembly and center exhaust pipe assembly with the 2 compression springs and 4 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

|

(f) Connect the heated oxygen sensor connector. |

|

9. INSPECT FOR EXHAUST GAS LEAK

.gif)

10. INSTALL NO. 2 ENGINE UNDER COVER

11. INSTALL NO. 1 ENGINE UNDER COVER

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Wear protective gloves when removing the exhaust pipe.

The exhaust pipe is extremely hot immediately after the engine has stopped.

...

Exhaust Pipe

Exhaust Pipe

...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE REAR DOOR INSIDE HANDLE BEZEL PLUG

3. REMOVE REAR P ...

Sliding Roof does not Move by Operating Sliding Roof Control Switch

DESCRIPTION

The sliding roof ECU (sliding roof drive gear sub-assembly) receives switch slide

and tilt signals and drives its built-in motor.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system ...

Fuel Receiver Gauge Malfunction

DESCRIPTION

The meter CPU uses the fuel sender gauge assembly to determine the level

of the fuel in the fuel tank. The resistance of the fuel sender gauge will

vary between approximately 7.5 Ω with the float at the full position, and

185 Î ...

0.1732

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)