Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT SPIRAL CABLE

(a) Visually check for defects with the spiral cable removed from the vehicle.

(1) The defects are as follows:

- Scratches on the spiral cable

- Small cracks the spiral cable

- Dents on the spiral cable

- Chips on the spiral cable

- Cracks or other damage to the connector

OK:

No defects are found.

HINT:

If any of the defects is found, replace the spiral cable with a new one.

|

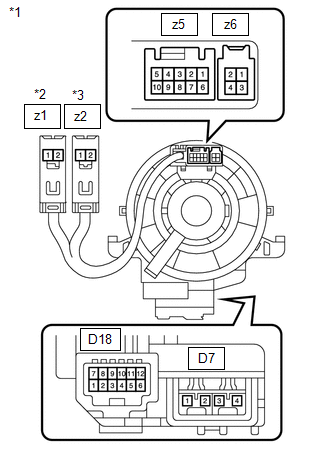

(b) Inspect the spiral cable. Text in Illustration

(1) Measure the resistance according to the value(s) in the table below. NOTICE: To avoid breakage of the spiral cable, do not turn the spiral cable more than necessary. If the value is not within the specified range, replace the spiral cable. Standard Resistance

|

|

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

2. TURN FRONT WHEELS TO FACE STRAIGHT AHEAD

3. DISCONNECT CABLE FROM NEGATIVE BATTE ...

Other materials about Toyota Venza:

Torque Sensor Zero Point Adjustment Incomplete (C1516,C1526)

DESCRIPTION

These DTCs do not indicate a malfunction. The power steering ECU stores these

DTCs when it determines that the rotation angle sensor value initialization and

torque sensor zero point calibration are incomplete.

DTC No.

D ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF REAR SHOCK ABSORBER

(a) Fully extend the shock absorber piston rod.

(b) Using a drill, make a hole in area B shown in the illustration to discharge

the gas inside. ...

0.1811