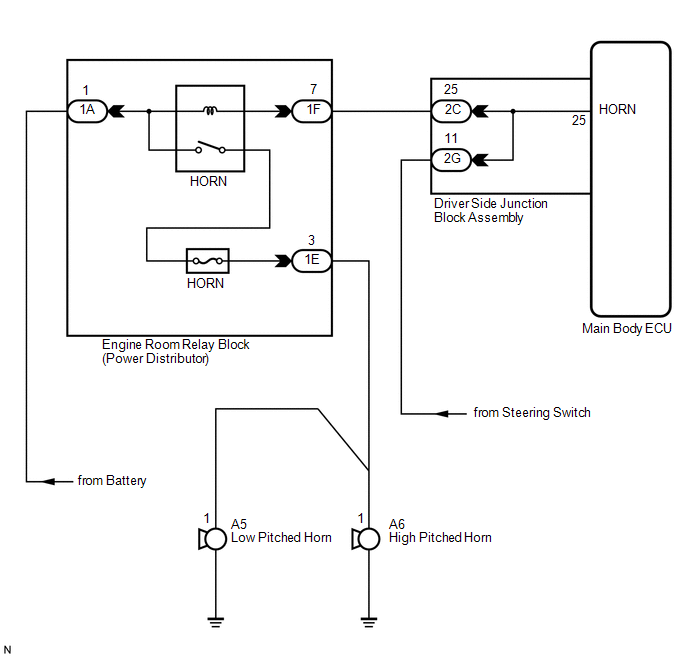

Toyota Venza: Horn Circuit

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm sounding state, the main body ECU (driver side junction block assembly) transmits a signal to cause the horn to sound at intervals of 0.4 seconds.

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT HORNS |

(a) Press the horn switch and check if the horns sound.

|

Result |

Proceed to |

|---|---|

|

Horns sound |

A |

|

Horns do not sound |

B |

| B | .gif) |

GO TO HORN SYSTEM |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Select the item below in the Active Test and then check that the horns operate.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Horn |

Vehicle horns |

ON / OFF |

- |

OK:

The vehicle horns sound and stop correctly when operated through the Techstream.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

Engine Hood Courtesy Switch Circuit

Engine Hood Courtesy Switch Circuit

DESCRIPTION

The security courtesy switch is installed together with the hood lock. This switch

turns off when the engine hood is opened and turns on when the engine hood is closed.

WIRING DIAGRAM

...

Security Horn Circuit

Security Horn Circuit

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm

sounding state, the main body ECU (driver side junction block assembly) controls

the security horn.

WIRI ...

Other materials about Toyota Venza:

USB Media Malfunction (B1585)

DESCRIPTION

This DTC is stored when a malfunction occurs in a connected device.

DTC No.

DTC Detection Condition

Trouble Area

B1585

When any of the following conditions is met:

A non m ...

Accelerator Pedal

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT ACCELERATOR PEDAL SENSOR ASSEMBLY

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) En ...

Push Switch / Key Unlock Warning Switch Malfunction (B2780)

DESCRIPTION

This DTC is stored if the transponder key ECU assembly does not detect that the

unlock warning switch assembly is ON even when the ignition switch is ON. Under

normal conditions, the unlock warning switch assembly is ON when the ignition switc ...

0.138

.gif)