Toyota Venza: Front seats

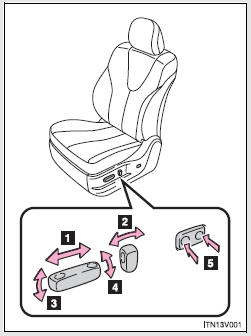

► Power seat

1. Seat position fore/aft control switch 2. Seatback angle control switch 3. Seat cushion (front) angle control switch (driver’s side only) 4. Vertical height control switch (driver’s side only) 5. Lumbar support control switch

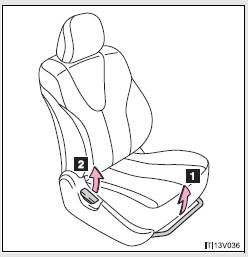

► Manual seat

1. Seat position fore/aft adjustment lever 2. Seatback angle adjustment lever

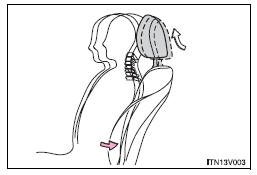

Active head restraints

When the occupant’s lower back presses against the seatback during a rear-end collision, the head restraint moves slightly forward and upward to help reduce the risk of whiplash on the seat occupant.

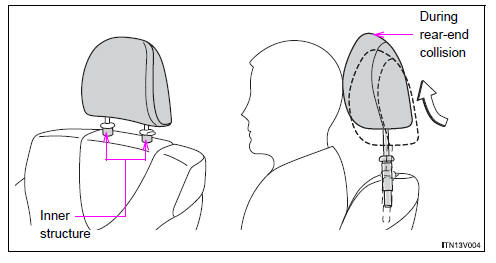

- Active head restraints

Even small forces applied to the seatback may cause the head restraint to move. Pushing up a locked head restraint forcibly may make the inner structure of the head restraint appear. This does not indicate a problem.

CAUTION

- Seat adjustment

• Be careful that the seat does not hit passengers or luggage.

• Do not recline the seat more than necessary when the vehicle is in motion to reduce the risk of sliding under the lap belt.

If the seat is too reclined, during an accident the lap belt may slide past the hips and apply restraint forces directly to the abdomen or your neck may contact the shoulder belt, increasing the risk of death or serious injury.

• Manual seat only: After adjusting the seat, make sure that the seat is locked in position.

Rear seats

Rear seats

Seatback angle adjustment lever

Pull up the lever until the lock is completely released.

Folding down the rear seatbacks

- Before folding down the rear seatbacks

Stow the seat belt buckl ...

Other materials about Toyota Venza:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the engine assembly (See page

).

PROCEDURE

1. INSTALL ENGINE HANGERS

2. REMOVE ENGINE STAND

(a) Remove the engine stand.

3. INSTALL ENGINE WIRE

...

Motor Circuit Malfunction (C1522-C1555)

DESCRIPTION

The power steering ECU supplies current to the power steering motor through the

motor circuit.

DTC No.

DTC Detection Condition

Trouble Area

C1522

Motor current sensor malfunction

...

Intermediate Shaft Speed Sensor "A" Circuit (P0791,P0793)

DESCRIPTION

This sensor detects the rotation speed of the counter gear which shows the output

speed of transaxle. By comparing the input turbine speed signal (NT) with the counter

gear speed sensor signal (NC), the TCM detects the shift timing of the gear ...

0.1198