Toyota Venza: Drive Belt

Components

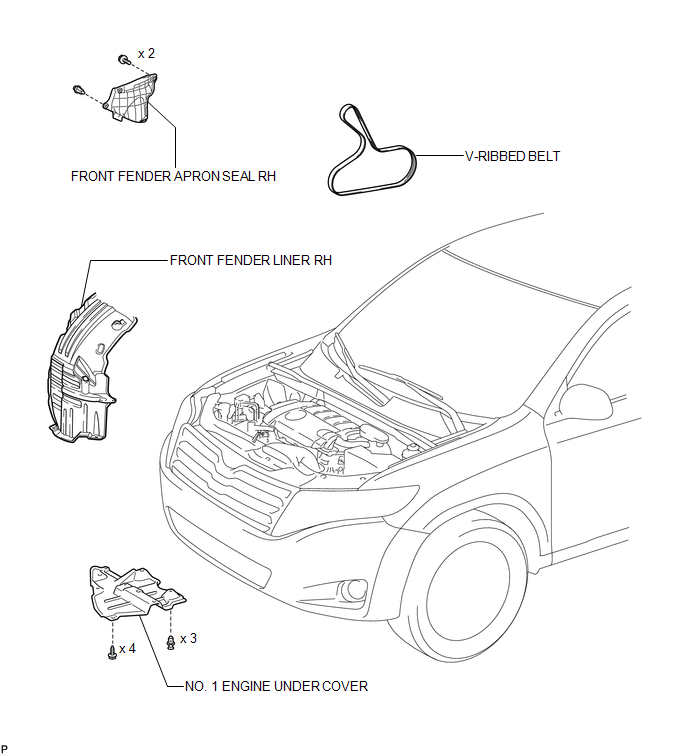

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT V-RIBBED BELT

|

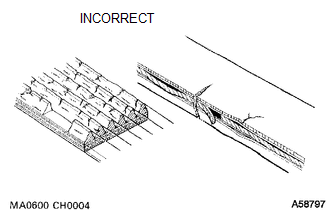

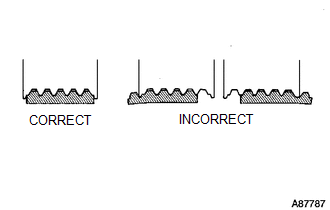

(a) Check the belt for wear, cracks or other signs of damage. If any of the following defects is found, replace the V-ribbed belt.

|

|

|

(b) Check that the belt fits properly in the ribbed grooves. HINT: Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly. |

|

2. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

(a) Check that nothing gets caught in the tensioner by turning it clockwise and counterclockwise.

If a malfunction exists, replace the V-ribbed belt tensioner.

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE NO. 1 ENGINE UNDER COVER

3. SEPARATE FRONT FENDER LINER RH

4. REMOVE FRONT FENDER APRON SEAL RH

.gif)

5. REMOVE V-RIBBED BELT

|

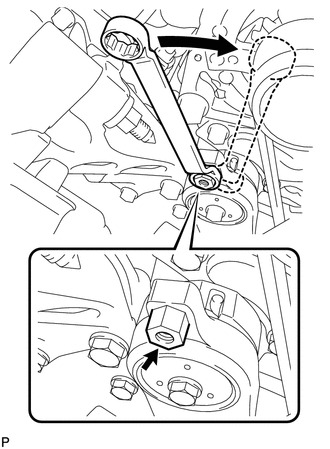

(a) Attach a wrench to the hexagonal portion of the belt tensioner as shown in the illustration, rotate the belt tensioner clockwise, and remove the V-ribbed belt. |

|

Installation

INSTALLATION

PROCEDURE

1. INSTALL V-RIBBED BELT

|

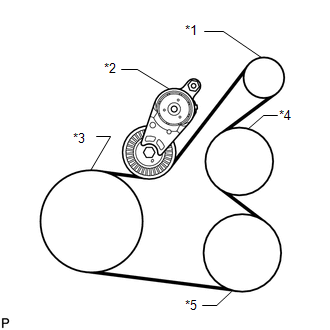

(a) Set the V-ribbed belt onto each part as shown in the illustration except the water pump pulley. Text in Illustration

|

|

(b) Loosen the V-ribbed belt by turning the belt tensioner clockwise.

(c) Set the V-ribbed belt onto the water pump pulley.

NOTICE:

Make sure that the belt is attached to each pulley. In particular, make sure that the belt is securely fitted into the grooves of the crankshaft pulley.

2. INSTALL FRONT FENDER APRON SEAL RH

.gif)

3. INSTALL FRONT FENDER LINER RH

4. INSTALL NO. 1 ENGINE UNDER COVER

5. INSTALL FRONT WHEEL RH

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly, camshaft timing exhaust gear as ...

Engine

Engine

...

Other materials about Toyota Venza:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY

(a) Apply a light layer of lithium soap base glycol grease to the entire circumference

of 2 new brake master cylinder reservoir grommets.

(b) Install the 2 brake master cylinder res ...

Correct driving posture

Drive with a good posture as follows:

1. Sit upright and well back in the seat.

2. Adjust the position of the seat forward or backward to ensure the pedals can

be reached and easily depressed to the extent required. 3. Adjust the seatback so

that the c ...

P/W Master Switch Communication Stop (B1206)

DESCRIPTION

This DTC is stored when LIN communication between the multiplex network master

switch assembly and main body ECU (driver side junction block assembly) stops for

more than 10 seconds.

DTC No.

DTC Detection Condition

...

0.1638