Toyota Venza: Vehicle Speed Sensor Malfunction (B2283)

DESCRIPTION

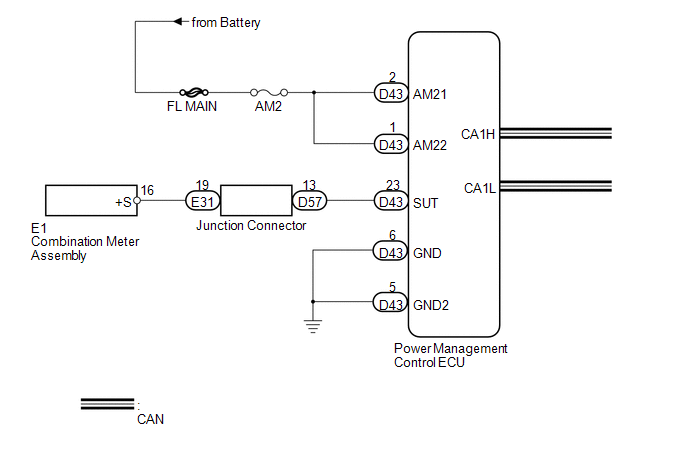

The skid control ECU converts wheel speed sensor signals into 4-pulse signals and sends them to the combination meter. After this signal is converted into a more precise rectangular waveform by the waveform shaping circuit inside the combination meter, it is then transmitted to the power management control ECU. The power management control ECU determines the vehicle speed based on the frequency of these pulse signals.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B2283 |

Both conditions are met:

|

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When the power management control ECU is replaced with a new one and the cable from the negative (-) battery terminal is connected, the power source mode becomes the on (IG) mode. When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

.gif)

| NG | .gif) |

GO TO CAN COMMUNICATION SYSTEM |

|

|

2. |

CHECK SPEEDOMETER OPERATION |

.gif)

| NG | .gif) |

GO TO METER / GAUGE SYSTEM (Speedometer Malfunction) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - POWER MANAGEMENT CONTROL ECU) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER MANAGEMENT CONTROL ECU - BODY GROUND) |

|

|

5. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER - POWER MANAGEMENT CONTROL ECU) |

.gif)

| NG | .gif) |

GO TO STEP 8 |

|

|

6. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Power Source Control / Data List.

(e) Read the Data List according to the display on the Techstream.

Power Source Control|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Speed Signal |

Vehicle speed signal/Stop or Run |

Stop: Vehicle stopped Run: Vehicle running |

- |

OK:

Stop (vehicle is stopped) and Run (vehicle is running) appear on the screen.

| NG | .gif) |

GO TO METER / GAUGE SYSTEM (Speedometer Malfunction) |

|

|

7. |

CHECK SPEED SIGNAL INPUT STATUS |

.gif)

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

GO TO METER / GAUGE SYSTEM (Speed Signal Circuit) |

|

8. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - NO. 1 JUNCTION BLOCK) |

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (COMBINATION METER - NO. 1 JUNCTION BLOCK) |

|

|

9. |

CHECK HARNESS AND CONNECTOR (NO. 1 JUNCTION BLOCK - POWER MANAGEMENT CONTROL ECU) |

.gif)

| OK | .gif) |

REPLACE NO. 1 JUNCTION CONNECTOR |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (NO. 1 JUNCTION BLOCK - POWER MANAGEMENT CONTROL ECU) |

Steering Lock Position Signal Circuit Malfunction (B2285)

Steering Lock Position Signal Circuit Malfunction (B2285)

DESCRIPTION

This DTC is stored when serial communication signals and LIN communication signals

in the circuit between the power management control ECU and steering lock actuator

assembly (steerin ...

Ignition Hold Monitor Malfunction (B2271)

Ignition Hold Monitor Malfunction (B2271)

DESCRIPTION

This DTC is stored when a problem such as an open in the AM2 fuse, an open or

short in the wire harness between the fuse and power management control ECU, a short

in the IG output cir ...

Other materials about Toyota Venza:

Poor Sound Quality in All Modes (Low Volume)

PROCEDURE

1.

CHECK AUDIO SETTINGS

(a) Set treble, middle and bass to the initial values and check that the sound

is normal.

OK:

The sound returns to normal.

HINT:

Sound quality adjustment measures vary according to the ...

Rear Power Window RH Auto Up / Down Function does not Operate with Rear Power

Window Switch RH

DESCRIPTION

If the manual up/down function can be performed but the auto up/down function

cannot, the fail-safe mode may be functioning.

If the power window initialization (See page

) has not been performed, the auto up/down function

will not operate.

...

Check Mode Procedure

CHECK MODE PROCEDURE

1. CHECK MODE (SIGNAL CHECK): DTC CHECK

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / SRS Ai ...

0.1199

.gif)