Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT GARAGE DOOR OPENER

|

(a) To inspect the garage door opener system, press each switch and check that the LED in the "HomeLink" logo illuminates as illustrated. If one or more of the switches do not cause the LED to illuminate, confirm that the fuse and the wiring to the garage door opener system unit is normal. If the fuse and wiring are normal, and the LED does not illuminate, replace the garage door opener system unit located in the roof console box assembly. |

|

2. INSPECT GARAGE DOOR OPENER REGISTRATION AND TRANSMITTING

HINT:

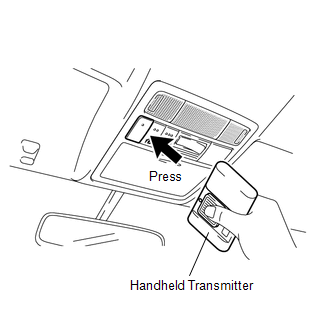

Use the KENT-MOORE "HomeLink" tester, and the KENT-MOORE handheld transmitter for this test. First clear the customer's transmitter codes, and then register the code of the KENT-MOORE handheld transmitter to the garage door opener system.

|

(a) Check if the code of the KENT-MOORE handheld transmitter was successfully registered. HINT: If the code of the KENT-MOORE handheld transmitter cannot be registered, replace the garage door opener system unit. |

|

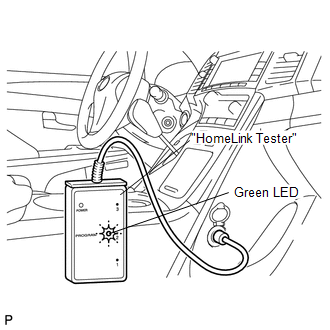

(b) Press the garage door opener switch that was used to copy the signal from the handheld transmitter. Check if the green LED of the "HomeLink" tester illuminates.

HINT:

If the green LED does not illuminate, replace the garage door opener system unit that is located in the roof console box assembly.

(c) When the inspection is complete, re-register the customer's handheld transmitter codes.

System Description

System Description

SYSTEM DESCRIPTION

1. DESCRIPTION

(a) A maximum of 3 codes for transmitter-code based systems such as garage doors

gates and entry gates can be registered to the vehicle garage door opener system. ...

Other materials about Toyota Venza:

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK FOR FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

(a) Check fuel pump operation.

(1) Connect the Techstream to the DLC3.

(2) Turn the ignition switch to ON and turn the Techstream on.

NOTICE:

Do not start the eng ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR WHEELS

2. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the center exhaust pipe assembly.

HINT:

Refer to the instructions for Removal of the exhaust pipe (See page

for 2GR-FE,

for 1AR-FE).

3. REMOVE LOWER NO. 1 EXH ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater Syste ...

0.1324

.png)

.png)