Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL HEATED OXYGEN SENSOR

.gif)

2. INSTALL FRONT EXHAUST PIPE ASSEMBLY

|

(a) Using a vernier caliper, measure the free length of the compression springs. Minimum Free Length: 41.5 mm (1.63 in.) If the free length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the exhaust manifold converter sub-assembly.

|

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the exhaust manifold converter sub-assembly. Text in Illustration

NOTICE:

|

|

|

(d) Install the front exhaust pipe assembly to the exhaust manifold converter sub-assembly with the 2 bolts and 2 compression springs. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

(e) Connect the heated oxygen sensor connector.

3. INSTALL CENTER EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

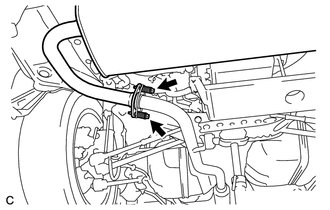

(b) Connect the center exhaust pipe assembly to the 2 exhaust pipe supports.

|

(c) Install the center exhaust pipe assembly to the front exhaust pipe assembly with the 2 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

4. INSTALL TAIL EXHAUST PIPE ASSEMBLY

|

(a) Using a vernier caliper, measure the free length of the compression springs. Minimum Free Length: 38.5 mm (1.52 in.) If the free length is less than the minimum, replace the compression spring. |

|

(b) Temporarily install a new gasket to the center exhaust pipe assembly.

|

(c) Using a plastic hammer and wooden block, tap in the gasket until its surface is flush with the center exhaust pipe assembly. Text in Illustration

NOTICE:

|

|

(d) Connect the tail exhaust pipe assembly to the 4 exhaust pipe supports.

|

(e) Install the tail exhaust pipe assembly to the center exhaust pipe assembly with the 2 bolts and 2 compression springs. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

5. INSTALL TAIL EXHAUST PIPE BAFFLE SUB-ASSEMBLY

|

(a) Align the cutout of the tail exhaust pipe baffle sub-assembly with the protrusion of the tail exhaust pipe assembly as shown in the illustration. Text in Illustration

|

|

(b) Using a plastic hammer, uniformly tap the tail exhaust pipe baffle sub-assembly onto the tail exhaust pipe assembly.

6. INSPECT FOR EXHAUST GAS LEAK

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

(a) Perform "Inspection After Repair" after repairing an exhaust gas leak (See

page .gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Wear protective gloves when removing the exhaust pipe.

The exhaust pipe is extremely hot immediately after the engine has stopped.

...

Other materials about Toyota Venza:

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT RR DEF RELAY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection

Condition

...

Window Glass Antenna Wire

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDOW GLASS ANTENNA WIRE

(a) Check for continuity of the antenna.

HINT:

Check for continuity at the center of each antenna wire as shown in the

illustration.

N ...

Power Back Door cannot be Closed Using the Power Back Door Closer Switch

DESCRIPTION

When the power back door cannot be closed using the power back door closer switch,

either of the following may be malfunctioning: 1) power back door closer switch

circuit or 2) power back door ECU (power back door motor unit).

WIRING DIAGRAM

...

0.1135

.png)

.png)