Toyota Venza: Front Blower Motor

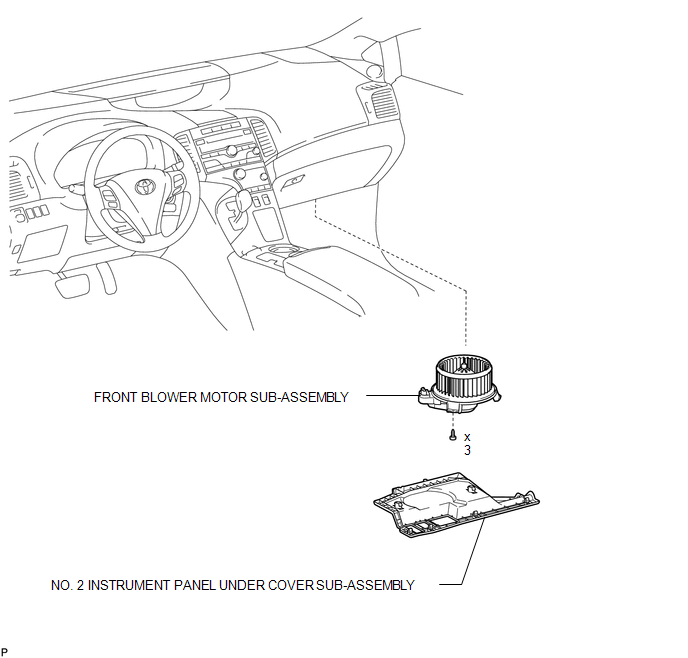

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

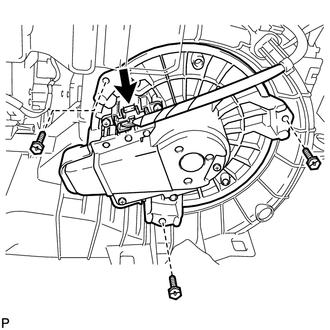

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Install the front blower motor sub-assembly with the 3 screws. |

|

(b) Connect the connector.

2. INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

.gif)

3. REMOVE FRONT BLOWER MOTOR SUB-ASSEMBLY

|

(a) Disconnect the connector. |

|

(b) Remove the 3 screws and front blower motor sub-assembly.

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL COOLER DRYER

(a) Using pliers, install a new cooler dryer to the modulator.

(b) Apply sufficien ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful because in ...

Removal

REMOVAL

PROCEDURE

1. REMOVE AIR CONDITIONING UNIT ASSEMBLY

(See page )

2. REMOVE NO. 1 FINISH PANEL MOUNTING BRACKET

3. REMOVE NO. 2 FINISH PANEL MOUNTING BRACKET

4. REMOVE NO. 3 AIR DUCT SUB-ASSEMBLY

5. REMOVE NO. 2 AIR DUCT SUB-ASSEMBLY

...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

(a) Install the front blower motor sub-assembly with the 3 screws.

2. INSTALL AIR INLET SERVO MOTOR SUB-ASSEMBLY

(a) Insta ...

0.1388

.png)