Toyota Venza: Replacement

REPLACEMENT

PROCEDURE

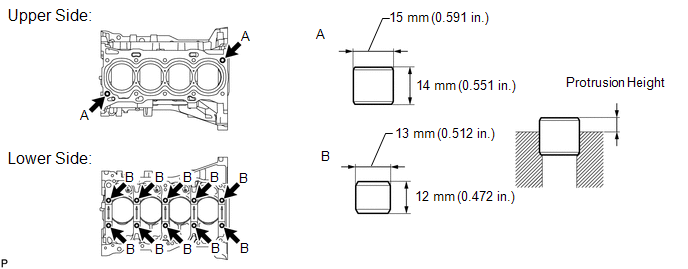

1. REPLACE RING PIN

NOTICE:

It is not necessary to remove the ring pin unless it is being replaced.

(a) Remove the 12 ring pins.

(b) Using a plastic-faced hammer, install 12 new ring pins.

Standard Protrusion Height:

|

Item |

Specified Condition |

|---|---|

|

A |

5.0 to 7.0 mm (0.197 to 0.276 in.) |

|

B |

4.0 to 7.0 mm (0.157 to 0.276 in.) |

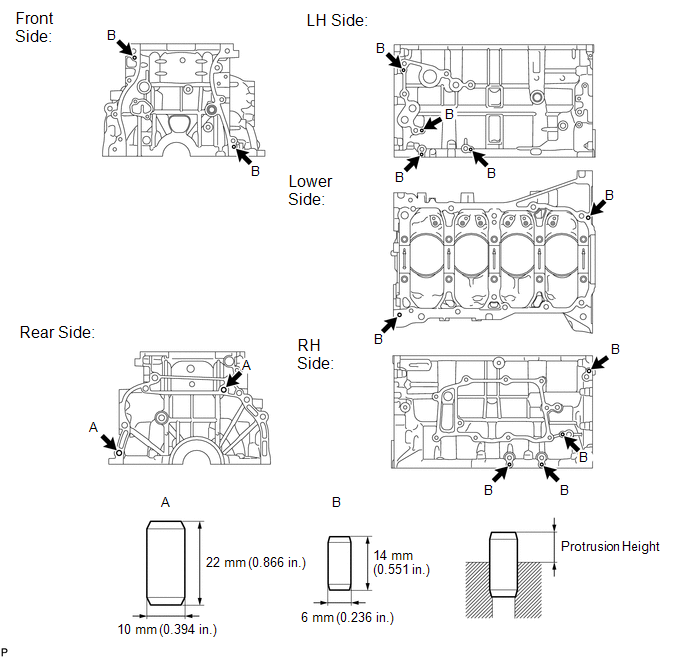

2. REPLACE STRAIGHT PIN

NOTICE:

It is not necessary to remove the straight pin unless it is being replaced.

(a) Remove the 14 straight pins.

(b) Using a plastic-faced hammer, install 14 new straight pins.

Standard Protrusion Height:

|

Item |

Specified Condition |

|---|---|

|

A |

11.0 to 13.0 mm (0.433 to 0.512 in.) |

|

B |

5.0 to 7.0 mm (0.197 to 0.276 in.) |

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the piston or piston ring (See

page ).

PROCEDURE

1. INSTALL STUD BOLT

NOTICE:

If a stud b ...

Cylinder Head

Cylinder Head

...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system.

NOTICE:

When disconnecting the cable, some systems ne ...

Precaution

PRECAUTION

1. PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following systems after the terminal is reconnected.

System Name

...

4WD Control ECU Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

4WD Control ECU Communication Stop Mode

"Four Wheel Drive Control" is not displayed on the "CAN Bus

Check" screen ...

0.1137