Toyota Venza: Power Back Door Warning Buzzer

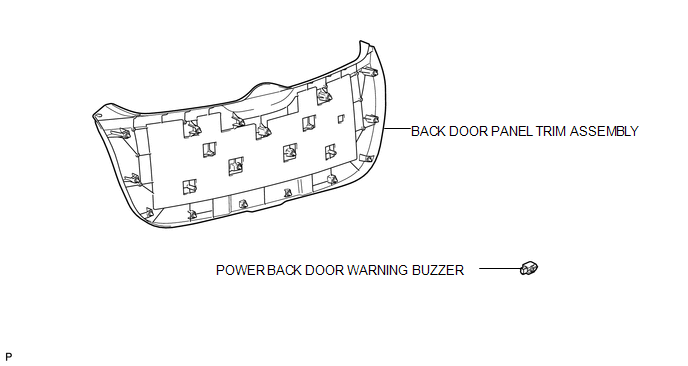

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER BACK DOOR WARNING BUZZER

|

(a) Measure the resistance according to the value(s) in the table below. HINT: If battery voltage is applied directly to the buzzer, the buzzer will not sound. Standard Resistance:

If the result is not as specified, replace the power back door warning buzzer. |

|

Removal

REMOVAL

PROCEDURE

1. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

.gif)

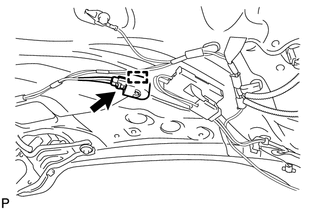

2. REMOVE POWER BACK DOOR WARNING BUZZER

|

(a) Disconnect the connector. |

|

(b) Disengage the clamp to remove the power back door warning buzzer.

Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER BACK DOOR WARNING BUZZER

|

(a) Engage the clamp to install the power back door warning buzzer. |

|

(b) Connect the connector.

2. INSTALL BACK DOOR PANEL TRIM ASSEMBLY

.gif)

Power Back Door Touch Sensor

Power Back Door Touch Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER BACK WINDOW PANEL TRIM

2. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

3. DISCONNECT POWER BACK DOOR ROD (for L ...

Rear Door

Rear Door

...

Other materials about Toyota Venza:

Removal

REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

Wear protective gloves when removing the exhaust pipe.

The exhaust pipe is extremely hot immediately after the engine has stopped.

Confirm that the exhaust pipe has cooled down ...

Rear Airbag Sensor RH Circuit Malfunction (B1630/23)

DESCRIPTION

The side collision sensor RH circuit (to determine deployment of the front seat

side airbag assembly RH and curtain shield airbag assembly RH) is composed of the

center airbag sensor assembly, rear airbag sensor RH and side airbag sensor RH.

...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

Do not replace the spiral cable with the battery connected and the ignition

switch ON.

Do not rotate the spiral cable without the steering wheel with the battery

connected and the ignition swi ...

0.1319

.png)

.png)