Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL PARKING BRAKE PEDAL ASSEMBLY

|

(a) Install the parking brake pedal assembly with the 3 nuts. Torque: 21 N·m {214 kgf·cm, 15 ft·lbf} |

|

|

(b) Connect the parking brake switch connector. |

|

(c) Install the No. 1 parking brake cable assembly with the nut and 4 bolts.

.png)

Torque:

Nut :

5.4 N·m {55 kgf·cm, 48 in·lbf}

Bolt :

15 N·m {153 kgf·cm, 11 ft·lbf}

|

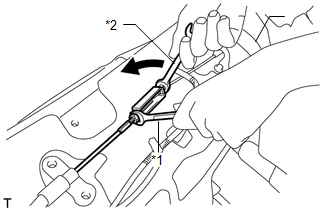

(d) Temporarily install the No. 1 wire adjusting nut and lock nut. Text in Illustration

HINT: After adjusting parking brake pedal travel, tighten the lock nut. |

|

|

(e) Engage the 4 clamps to install the wire harness. |

|

|

(f) Connect the 2 connectors. |

|

|

(g) Connect the heated oxygen sensor connector and engage the 2 clamps (for 2GR-FE). |

|

2. CONNECT NO. 4 PARKING BRAKE CABLE ASSEMBLY

|

(a) Holding the lock nut of the No. 1 parking brake cable assembly, tighten the turnbuckle of the No. 4 parking brake cable assembly to connect the No. 4 parking brake cable assembly to the No. 1 parking brake cable assembly. Text in Illustration

Torque: 5.4 N·m {55 kgf·cm, 48 in·lbf} |

|

3. INSTALL FRONT NO. 2 FLOOR SILENCER

|

(a) Install the front No. 2 floor silencer. |

|

4. INSTALL REAR NO. 1 AIR DUCT

.gif)

5. INSTALL REAR NO. 2 AIR DUCT

.gif)

6. INSTALL YAW RATE AND ACCELERATION SENSOR

HINT:

Refer to the instructions for Installation of the yaw rate and acceleration sensor

(See page .gif) ).

).

7. ADJUST PARKING BRAKE SHOE CLEARANCE AND PARKING BRAKE PEDAL TRAVEL

.gif)

8. INSPECT BRAKE WARNING LIGHT

.gif)

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL PARKING PEDAL PAD

(a) Install the parking pedal pad to the parking brake pedal assembly.

2. INSTALL PARKING BRAKE SWITCH ASSEMBLY

3. INSTALL NO. 1 PARKING BRAKE ...

Other materials about Toyota Venza:

Cooling System

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap while the engine and radiator are still hot. Pressurized

hot engine coolant and steam may be released and cause serious burns.

N ...

Random / Multiple Cylinder Misfire Detected (P0300-P0304)

DESCRIPTION

When the engine misfires, high concentrations of hydrocarbons (HC) enter the

exhaust gas. Extremely high hydrocarbon concentration levels can cause an increase

in exhaust emission levels. Extremely high concentrations of hydrocarbons can also ...

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE UPPER BACK WINDOW PANEL TRIM

(a) Disengage the 4 clips and 4 claws, and remove the upper back window

panel trim.

2. REMOVE BACK DOOR PANEL TRIM ASSEMBLY

...

0.1347

.png)

.png)

.png)

.png)

.png)

.png)

.png)