Toyota Venza: Headlight Signal Circuit

DESCRIPTION

The headlight leveling ECU assembly detects the low beam headlights status.

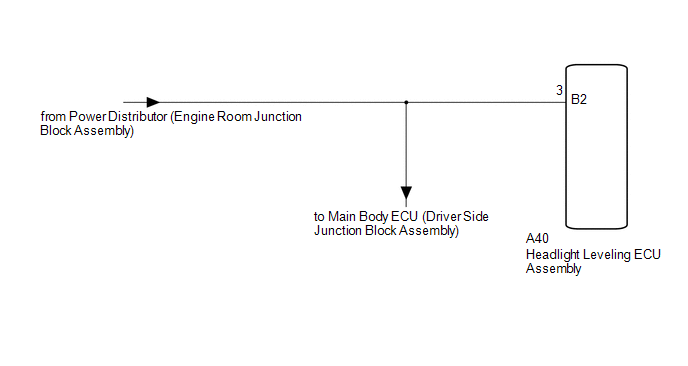

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

First check that the low beam headlights operate normally.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (ENGINE ROOM JUNCTION BLOCK ASSEMBLY - ECU) |

|

(a) Disconnect the A40 headlight leveling ECU assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A40-3 (B2) - Body ground |

Light control switch in head position |

11 to 14 V |

|

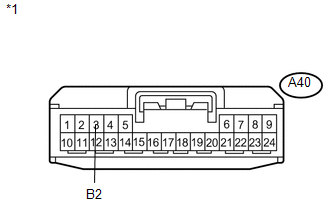

*1 |

Front view of wire harness connector (to Headlight Leveling ECU assembly) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Front Fog Light Circuit

Front Fog Light Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the fog light

relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this ...

Light Control Switch Circuit

Light Control Switch Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) receives the following

switch information:

Light control switch position off, tail, head or AUTO

Dimmer switch positi ...

Other materials about Toyota Venza:

Indicators and warning lights

The indicator and warning lights on the instrument cluster and center panel

inform the driver of the status of the vehicle’s various systems.

For the purpose of explanation, the following illustration displays all indicators

and warning lights illuminat ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL INSTRUMENT PANEL WIRE ASSEMBLY

(a) Connect the vent hole connector of the instrument panel wire to the

front passenger airbag assembly.

Text in Illustration

*1

Vent Hol ...

Evaporative Emission Control System Incorrect Purge Flow (P0441)

DTC SUMMARY

DTC No.

Monitoring Item

Malfunction Detection Condition

Trouble Area

Detection Timing

Detection Logic

P0441

Purge VSV (Vacuum Switching Valve) stuck open ...

0.1574